In the rapidly evolving landscape of manufacturing, CNC drilling machines stand out as essential tools for businesses aiming to enhance productivity and precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.5 billion by 2026, growing at a CAGR of 6.9% from 2021. This surge is driven by the increasing demand for automated processes in industries such as automotive, aerospace, and electronics, where accuracy and efficiency are paramount.

As we approach 2025, understanding the top CNC drilling machines on the market will be crucial for businesses looking to optimize their operations. These machines not only facilitate high-speed drilling but also support complex manufacturing tasks, thereby reducing lead times and operational costs. A comprehensive review of the leading CNC drilling machines can provide insights into the latest technological advancements, enabling companies to make informed purchasing decisions that align with their strategic goals.

The significance of CNC drilling machines extends beyond mere functionality; they embody the future of manufacturing. By leveraging the capabilities of advanced CNC systems, businesses can enhance their production capabilities, ensure quality control, and remain competitive in an ever-changing market landscape. This article will delve into the top CNC drilling machines of 2025 that every business should consider to thrive in this dynamic environment.

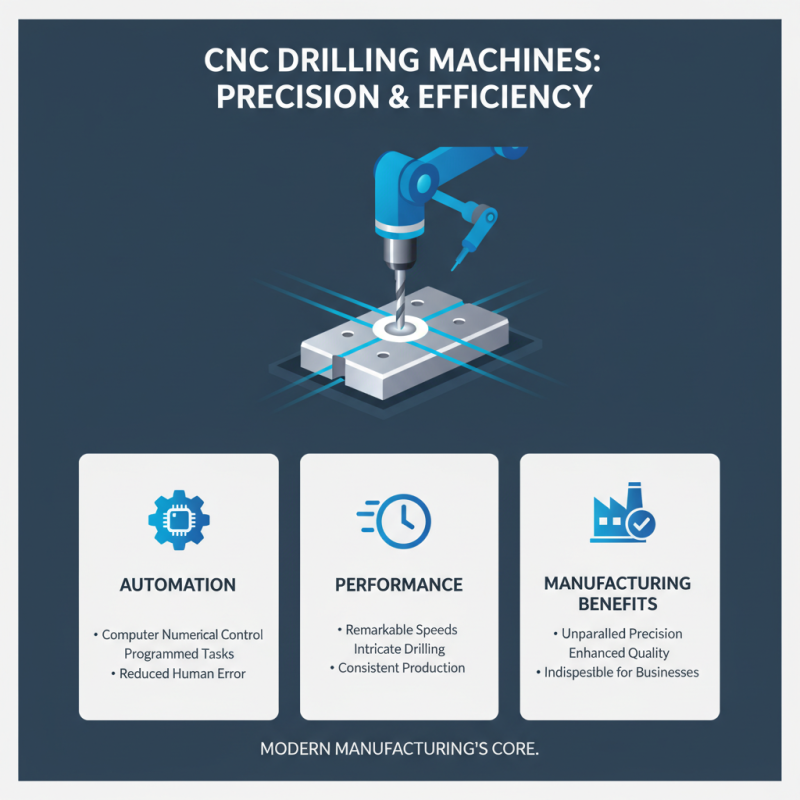

CNC drilling machines play a crucial role in modern manufacturing processes, offering unparalleled precision and efficiency. Unlike traditional drilling methods, CNC (Computer Numerical Control) machines are automated and programmed to perform intricate drilling tasks at remarkable speeds. This level of automation significantly reduces human error and enhances production consistency, making these machines indispensable for businesses aiming to maintain high quality standards.

In today’s competitive landscape, the importance of CNC drilling machines extends beyond mere productivity. These machines allow for complex designs that meet the evolving needs of various industries, including aerospace, automotive, and electronics. By integrating CNC technology, companies can optimize their workflows, minimize waste, and improve turnaround times. Additionally, the ability to program multiple drilling tasks into a single machine helps streamline operations, further solidifying the significance of CNC drilling technology in driving business growth and innovation.

When selecting the top CNC drilling machines for 2025, businesses should prioritize several key features that can significantly enhance productivity and precision. One of the most critical factors is the machine's speed and feed rates. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.7 billion by 2025, with high-speed drilling capabilities being a major driver of this growth. Machines offering rapid spindle speeds and optimal feed rates minimize cycle times, leading to increased output and efficiency.

Another essential feature to consider is the software compatibility of CNC drilling machines. The integration of advanced CAD/CAM software solutions enables better design flexibility and improved machining processes. A study published in the Journal of Manufacturing Processes highlights that CNC machines equipped with intelligent software tools can reduce programming times by up to 30%. Furthermore, machines that support IoT connectivity allow for real-time monitoring and predictive maintenance, helping to lower operational downtime in a competitive manufacturing landscape.

Lastly, accuracy and repeatability remain paramount. Modern CNC drilling machines should feature temperature-controlled systems and advanced motion control technologies to ensure high precision. According to a report from Allied Market Research, the demand for high-precision machining is expected to rise significantly as industries like aerospace and automotive continue to require tight tolerances for components. Investing in machines that prioritize these features will enable businesses to maintain a competitive advantage in an evolving market.

When selecting a CNC drilling machine for your business, understanding the top manufacturers in the industry is crucial. Leading companies such as Haas Automation, DMG Mori, and Mazak have established themselves as benchmarks of reliability and precision. Haas Automation is known for its user-friendly controls and robust build quality, making it a popular choice for small to medium-sized enterprises. DMG Mori combines German engineering excellence with cutting-edge technology, providing high-performance machines that excel in complex drilling tasks. Mazak, on the other hand, offers advanced multi-tasking capabilities, allowing for increased efficiency and versatility in production.

In addition to these giants, it’s important to consider emerging players like Amada and Fanuc, which are gaining traction for their innovative designs and tailored solutions. Amada specializes in providing CNC machines that integrate well with sheet metal fabrication, while Fanuc is renowned for its automation technology, enhancing productivity through smart features. Evaluating these manufacturers helps businesses not only choose the right equipment but also align their production goals with the latest advancements in CNC drilling technology.

When it comes to selecting the best CNC drilling machines for your business in 2025, conducting a comparative analysis is essential. The market offers several options, each with unique features tailored to specific industries. For instance, machines that provide high-speed drilling capabilities are ideal for precision work, while those with larger torque settings are better suited for heavy-duty applications. Evaluating the specifications of each model against your operational needs can help you make an informed decision.

Tips: Always consider the reliability of the manufacturer and the availability of customer support. Investing in machines from reputable brands can ensure longevity and ease of maintenance. Also, keep in mind the scalability of the equipment. Your choice should not only fit your current production demands but also allow room for future growth.

In addition, look into the software compatibility of the CNC drilling machines. Modern machines often come equipped with advanced CNC software that enhances performance and efficiency. Ensure that the machine you choose can seamlessly integrate with your existing systems to minimize disruptions. This consideration can significantly influence your overall productivity in the long run.

The market for CNC drilling technology is witnessing significant advancements as businesses increasingly adopt these systems to improve precision and efficiency. One notable trend is the integration of hybrid methods that combine traditional machining with CNC operations, particularly in the woodworking industry. This approach enables manufacturers to produce high-quality timber products with superior accuracy, ultimately increasing their competitiveness in the marketplace. As a result, the woodworking machinery segment is experiencing substantial growth, highlighting the vital role of CNC technology in enhancing manufacturing capabilities.

Furthermore, the evolution of CNC drilling machines is poised to influence various sectors, ranging from aerospace to automotive. The incorporation of advanced features such as real-time monitoring and adaptive control systems allows for more precise drilling operations, which are essential for meeting the stringent requirements of modern applications. As companies continue to invest in these technologies, the potential for improved productivity and reduced waste becomes increasingly apparent, indicating that CNC drilling will play a crucial role in shaping the manufacturing landscape in the coming years.

| Machine Model | Max Drilling Diameter (mm) | Drilling Speed (RPM) | Control Type | Applications |

|---|---|---|---|---|

| Model A | 20 | 6000 | CNC | Automotive Parts |

| Model B | 25 | 7500 | CNC | Aerospace Components |

| Model C | 30 | 5000 | CNC | Electronics Housing |

| Model D | 15 | 8000 | CNC | Medical Devices |

| Model E | 18 | 7000 | CNC | Construction Equipment |