In the world of woodworking and manufacturing, efficiency is key. Panel Drilling Machines play a crucial role in streamlining production processes. These machines help create precise holes in various panel materials, including plywood and MDF. This ensures high-quality output for furniture, cabinetry, and other applications.

As we explore the 2026 models, it's essential to consider their features and performance. Some machines stand out for their speed and accuracy. Others offer versatility, adapting to different panel sizes and thicknesses. However, a common issue is the learning curve associated with advanced technology. Users often find themselves facing challenges when operating new machines.

Understanding the strengths and weaknesses of each model is vital. This guide aims to provide insights on the top panel drilling machines available. By delving into specifications, user experiences, and expert reviews, we hope to help you make informed decisions. These insights may reveal aspects that require careful consideration before purchase.

The panel drilling machines of 2026 are set to revolutionize woodworking and industrial applications. These machines are designed to increase efficiency and precision. Their advanced features cater to various materials, making them versatile. Users can expect improvements in speed and accuracy. The intuitive controls simplify operations, though some operators may find the learning curve steep.

One notable advancement is the integration of smart technology. This allows for real-time monitoring of performance. Operators can receive alerts for maintenance, reducing downtime. Yet, despite these advancements, machine malfunctions still occur. Over-reliance on technology can lead to unexpected issues. Users should remain vigilant and conduct regular maintenance checks.

Ergonomics is another significant focus for 2026's models. Improved designs aim to reduce operator fatigue during long hours. However, some machines may still be heavy and cumbersome. This can deter some users from fully embracing the latest innovations. It reminds us to balance technology with human factors for optimal productivity.

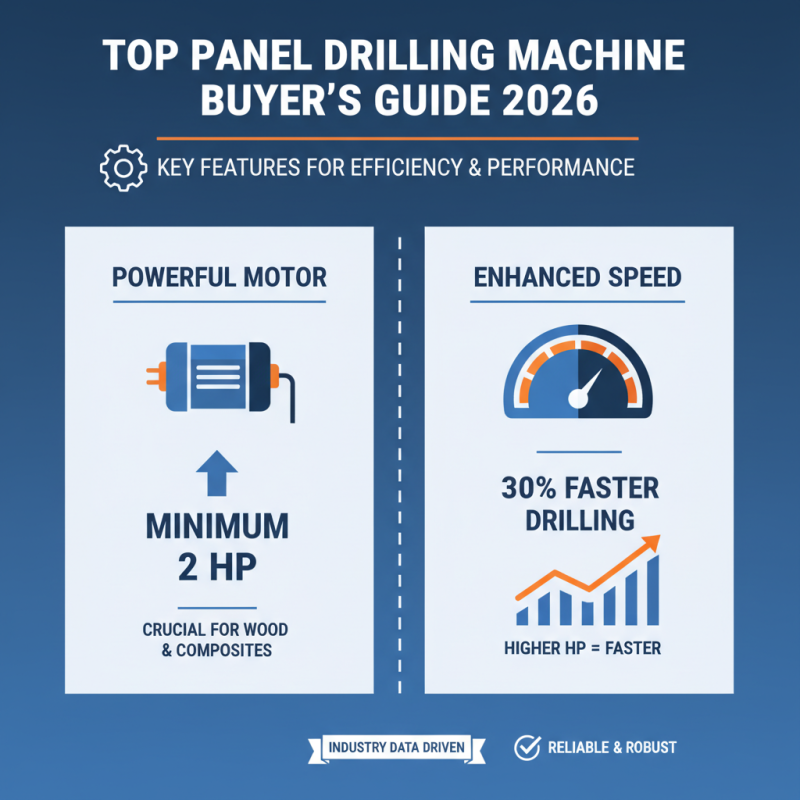

When selecting a top panel drilling machine in 2026, focus on key features that enhance performance and efficiency. A reliable machine should have a sturdy motor with at least 2 HP. This is crucial for handling various materials like wood and composites. According to industry data, machines with higher horsepower can improve drilling speed by up to 30%.

Another important feature is the depth adjustment mechanism. Precision is vital in drilling operations, especially in furniture manufacturing. Many reports indicate that machines with easy depth settings reduce the risk of errors, which can save time and resources. Additionally, a dust extraction system is essential for maintaining a clean working environment. Inefficient dust removal can lead to safety hazards and increased maintenance costs.

Moreover, consider the portability of the machine. While heavier machines offer stability, they can limit mobility. Users often find themselves constrained in workspace. A compact and lightweight design can enhance flexibility. However, this might compromise some drilling power or stability. Balancing these factors is a challenge all operators face. Focusing on the right features will improve productivity and reduce operational risks.

In 2026, the panel drilling machine market shows significant growth. Recent industry reports indicate a surge in demand, driven by advancements in technology. Many companies are investing heavily in automation features. These improvements enhance precision and efficiency, leading to higher production rates.

A comparative analysis of leading brands reveals distinct differences. Performance metrics vary, particularly in drilling speed and energy efficiency. Some models offer up to 30% quicker drilling times. Others prioritize minimal energy consumption, which is crucial for sustainability goals. However, some critiques highlight that certain machines struggle with material versatility. Their limitations may impact overall usability in diverse applications.

User feedback also indicates a need for better maintenance protocols. Reports suggest that even top-tier machines face downtime due to inadequate training for operators. This reveals a gap in user support and highlights areas for improvement. Ultimately, as technology evolves, manufacturers must address these shortcomings to stay competitive.

| Model | Power (HP) | Weight (lbs) | Max Depth (inches) | Price (USD) |

|---|---|---|---|---|

| Model A | 10 | 250 | 4 | 2,500 |

| Model B | 12 | 280 | 5 | 3,200 |

| Model C | 8 | 220 | 3 | 1,800 |

| Model D | 15 | 300 | 6 | 4,000 |

| Model E | 11 | 260 | 4.5 | 2,700 |

The panel drilling machine is a vital asset across various industries. This technology finds applications in sectors like furniture manufacturing, construction, and automotive industries. A recent industry report from Global Market Insights highlighted that the panel drilling machine market is projected to grow at a CAGR of 5.8% by 2026. This growth reflects the increasing demand for precision and efficiency in production processes.

In furniture manufacturing, these machines are indispensable for creating complex designs and ensuring consistency. For instance, furniture makers need accurate drilling for joints and fittings. Without this, the final product can suffer from structural weaknesses. Meanwhile, in construction, panel drilling machines assist in producing pre-fabricated components that speed up on-site assembly. This method allows for better resource management and reduced labor costs.

However, the adoption of these machines is not without challenges. Many industries face issues with upskilling workers to operate advanced machinery. As automation rises, workers often need training to manage new tools effectively. Consequently, companies must invest in education and support to maximize the efficiency of panel drilling operations. The balance between high-tech innovation and workforce readiness creates a crucial area for reflection and growth.

As we gaze into the future of panel drilling technology, several trends are emerging. Automation is becoming more prevalent. Smart machines can now adapt to various materials and drilling depths. This flexibility enhances production efficiency. However, the question remains: are we ready to handle the changes that come with automation?

Another exciting innovation is the use of advanced materials. Lightweight composites are increasingly being utilized. These materials can improve drilling accuracy and reduce wear on the machinery. But integrating these composites into existing processes can be challenging. Too often, companies overlook the necessary adjustments, leading to unexpected issues.

Sustainability is also at the forefront of future panel drilling technologies. Eco-friendly practices are gaining importance in manufacturing. Machines that minimize waste and energy consumption are in high demand. Yet, there is a gap in implementation. Many industries struggle to balance innovation with cost-effectiveness, creating a dilemma for stakeholders. Addressing these issues will be key to advancing the field.