In the rapidly evolving world of manufacturing, the advent of 5-Axis Machines is reshaping the landscape of precision machining. Renowned industry expert Dr. Emily Carter, a leading figure in advanced manufacturing technologies, emphasizes the transformative impact of these machines by stating, "The ability of 5-Axis Machines to perform intricate cuts and angles not only enhances precision but also streamlines the machining process, leading to unparalleled efficiency." This technology has revolutionized how complex components are produced, enabling engineers and machinists to achieve levels of accuracy previously unattainable with traditional 3-axis machines.

The integration of 5-Axis Machines into machining processes allows for a more comprehensive approach to manufacturing. By providing the capability to manipulate tools from multiple orientations, these machines significantly reduce setup times and material waste, thereby increasing productivity and cost-effectiveness. As industries continue to demand higher precision and faster turnaround times, the role of 5-Axis Machines has become indispensable in ensuring that manufacturers remain competitive in today’s fast-paced marketplace. The future of precision machining is undoubtedly tied to the advancements in 5-Axis technology, making it an essential area of exploration for professionals striving to innovate and optimize their machining capabilities.

5-axis machining technology represents a significant advancement in precision machining techniques, enabling manufacturers to produce complex geometries with unparalleled accuracy. Unlike traditional 3-axis machines, which move along three linear axes, 5-axis machines utilize two additional rotational axes. This capability allows workpieces to be approached from virtually any angle, contributing to a more efficient production process. According to a market research report by Grand View Research, the demand for 5-axis CNC machines is projected to witness a compound annual growth rate (CAGR) of 6.7% from 2021 to 2028, reflecting the growing need for precision components in industries such as aerospace, automotive, and medical devices.

The versatility offered by 5-axis machining goes beyond mere angle manipulation. As the machines operate with multiple degrees of freedom, they can significantly reduce the number of setup changes required during production. This not only streamlines workflow but also minimizes the risk of errors, leading to higher-quality output. A report from MarketsandMarkets highlights that implementing 5-axis machining can reduce manufacturing lead times by up to 20%, thereby enhancing overall productivity. As businesses increasingly adopt this technology, the potential for innovation in complex part design and reduced production costs becomes increasingly evident, solidifying 5-axis machining as a cornerstone of modern manufacturing processes.

5-axis machining has emerged as a game changer in the realm of precision machining, offering significant advantages over traditional machining methods. With the ability to move a tool or workpiece along five different axes simultaneously, these machines provide enhanced accuracy and flexibility. According to the 2021 TechTarget report, 5-axis machining can reduce production time by up to 75% compared to standard 3-axis methods, allowing for more complex geometries to be produced in fewer setups. This is particularly beneficial in industries like aerospace and medical device manufacturing, where precision is non-negotiable and lead times are critical.

Moreover, 5-axis machines minimize the need for fixtures and setups, which often introduce variability and potential errors. A study by the National Institute of Standards and Technology indicated that the adoption of 5-axis technology could lead to a 30% decrease in part production costs while improving repeatability and surface finish quality. As manufacturing industries move toward more sophisticated designs and tighter tolerances, the speed and efficiency of 5-axis machining position it as an essential tool for businesses aiming to stay competitive in a rapidly evolving marketplace.

5-axis machines have emerged as a game-changer in precision machining across various industries. Their ability to manipulate tools along five different axes simultaneously allows for the production of intricate components with a degree of accuracy previously unattainable with traditional 3-axis systems. According to a report by Allied Market Research, the global market for 5-axis machining is expected to reach $1.8 billion by 2025, highlighting the growing demand for advanced machining technologies. This trend is driven by industries such as aerospace, automotive, and medical device manufacturing, where precision and efficiency are paramount.

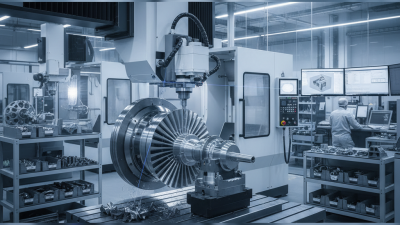

In the aerospace sector, 5-axis machines are often utilized to create complex geometries found in turbine blades and structural components. The ability to machine these parts in a single setup reduces cycle times and enhances accuracy, which is critical in an industry where even the slightest deviations can lead to catastrophic failures. Similarly, in the medical industry, 5-axis machining plays a vital role in fabricating custom implants and surgical instruments, allowing for personalized solutions that improve patient outcomes. The flexibility and precision offered by 5-axis technology are transforming manufacturing practices, leading to significant advancements in product quality and production efficiency across diverse applications.

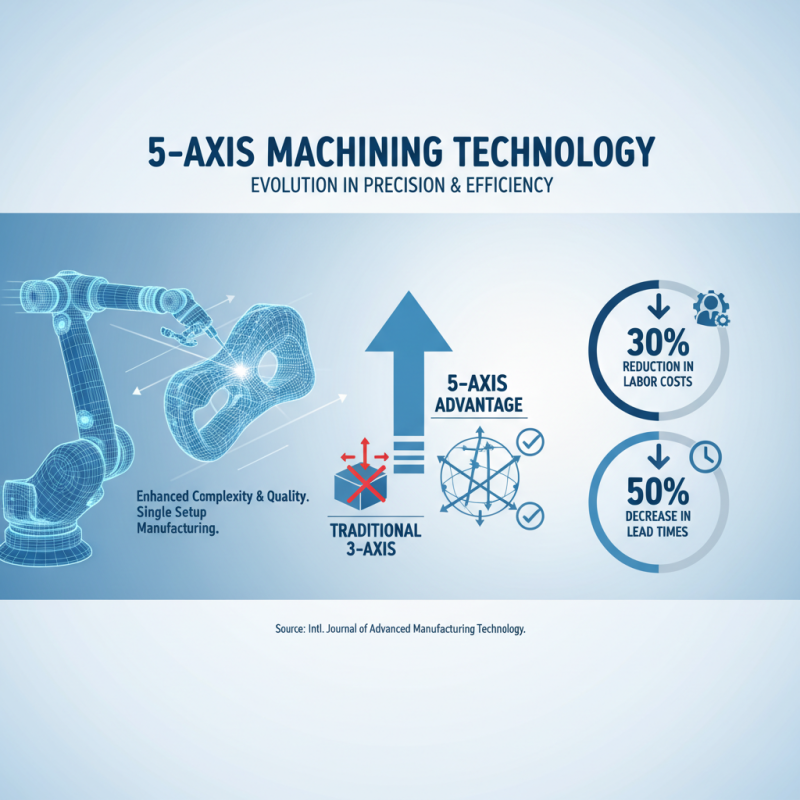

The advent of 5-axis machining technology has marked a significant evolution in the realm of precision machining, enhancing both efficiency and accuracy. Traditional CNC machining typically operates on three axes, which can limit the complexity and quality of the finished product. However, with 5-axis machines, manufacturers can perform intricate tasks in a single setup, reducing the need for multiple fixtures and setups that traditionally bog down production timelines. According to a study published by the International Journal of Advanced Manufacturing Technology, companies implementing 5-axis machines reported a reduction in labor costs by up to 30% and a 50% decrease in lead times, which is critical in a competitive manufacturing environment.

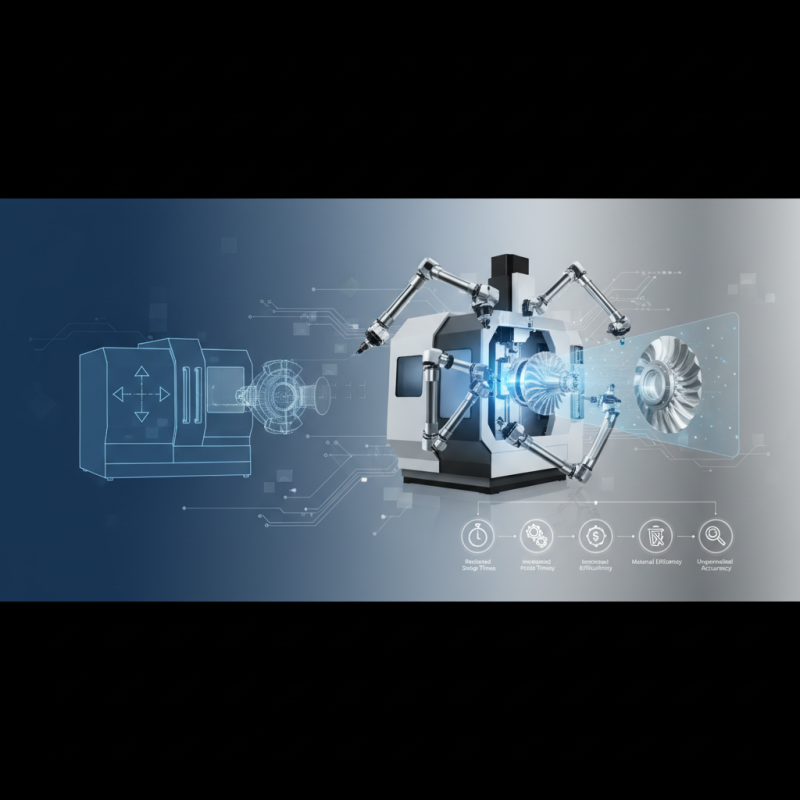

The precision gains with 5-axis machining are particularly noteworthy. These machines can achieve angular cuts and complex geometries that three-axis machines struggle with, thus ensuring tighter tolerances and better surface finishes. A report from the Association for Manufacturing Technology highlights that 5-axis auto-tool changers can enhance production rates by as much as 40% while maintaining high dimensional accuracy within ±10 microns. This capability not only factors into cost savings but also allows for greater material efficiency, leading companies to reduce waste and lower their overall production impacts. As 5-axis machining continues to evolve, its impact on precision and efficiency is poised to redefine industry standards, fostering a new era of innovative machining solutions.

The future of 5 axis machining technology presents exciting trends that are expected to redefine the landscape of precision engineering. As manufacturers increasingly adopt these advanced machines, the benefits of improved accuracy and efficiency become evident. According to a report by Research and Markets, the global market for 5 axis machining is projected to reach USD 5.92 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth underscores the expanding applications of 5 axis technology across various sectors, including aerospace, automotive, and medical device manufacturing.

One of the most significant trends is the integration of artificial intelligence (AI) and machine learning algorithms into 5 axis machining systems. These technologies can facilitate predictive maintenance and optimize machining processes, further enhancing operational efficiency. A study from the National Institute of Standards and Technology highlights that AI-driven real-time data analysis can reduce machining cycle times by up to 25%, allowing manufacturers to increase output without compromising quality. Additionally, the implementation of user-friendly interfaces and automation tools is making it easier for operators to leverage the full potential of 5 axis machining, thereby accelerating its adoption in small and medium-sized enterprises. As these technologies continue to evolve, the precision machining industry is poised for a transformative phase driven by 5 axis capabilities.