In the ever-evolving landscape of modern manufacturing, the adoption of advanced technologies is paramount to maintaining a competitive edge. Among these innovations, 5 Axis Machines have emerged as a game-changer, revolutionizing machining processes across various industries. With their ability to manipulate tools in multiple directions simultaneously, these machines offer unparalleled precision and efficiency, catering to the complex demands of contemporary production.

The implementation of 5 Axis Machines brings a multitude of benefits that not only enhance productivity but also improve the overall quality of manufactured products. By allowing for intricate designs and reducing the need for multiple setups, manufacturers can streamline operations and minimize lead times. Furthermore, the versatility of these machines supports a wide range of materials, making them indispensable in sectors such as aerospace, automotive, and medical device manufacturing. As we delve into the top ten benefits of utilizing 5 Axis Machines, it becomes evident that their integration signifies a transformative step forward in achieving operational excellence and innovation in manufacturing.

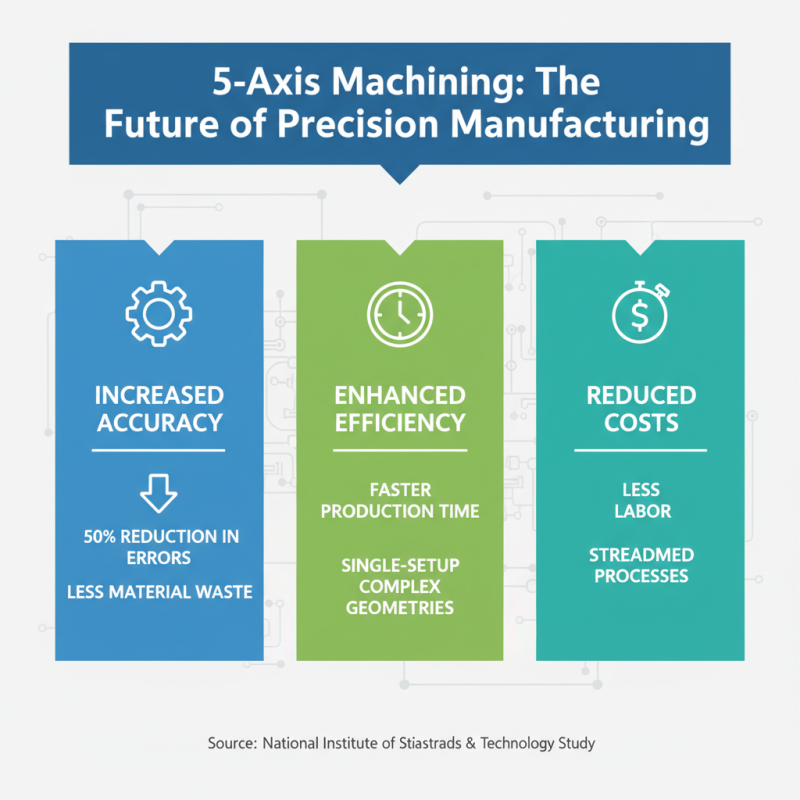

In modern manufacturing, the precision and accuracy that 5-axis machining offers are unparalleled, making it a vital asset for industries that demand intricate and high-quality components. According to a study by the National Institute of Standards and Technology, manufacturers leveraging 5-axis technology report a reduction in machining errors by up to 50%. This dramatic increase in accuracy translates to less material waste and a substantial decrease in production time, enhancing overall efficiency. Moreover, the ability to handle complex geometries in a single setup streamlines processes and significantly reduces the labor costs associated with multi-machine setups.

Tips: To maximize the benefits of 5-axis machining, ensure your programming software is fully optimized for complex part designs. Investing in good training for your operators can also drastically reduce setup times and improve overall output quality.

Additionally, the flexibility of 5-axis machining accommodates a wide variety of materials, including difficult-to-machine alloys and composites. Reports indicate that companies utilizing 5-axis machines can produce parts with tolerances as tight as ±0.005 inches, catering to sectors such as aerospace and automotive where precision is paramount. By facilitating advanced tool paths and minimizing tool changes during production, 5-axis technology enhances productivity while maintaining stringent quality standards.

Tips: Regular maintenance and calibration of your 5-axis equipment can avoid unforeseen downtime and maintain precision over time. Implementing a thorough quality control process will ensure consistent production and meet industry standards.

The use of 5-axis machines in modern manufacturing has ushered in a new era of design flexibility, largely due to their multi-angle cutting capabilities. Unlike traditional 3-axis machines, which limit operators to cutting along three linear axes, 5-axis machines can maneuver along additional angles, allowing for intricate designs and complex geometries to be processed in a single setup. According to a report by the International Federation of Robotics, the adoption of 5-axis machining centers has grown significantly, with a reported increase of 45% in usage across various manufacturing sectors over the last five years.

This enhanced design flexibility not only allows for greater creativity and innovation but also leads to improved efficiency and accuracy in production processes. A study published by the Journal of Manufacturing Science and Engineering noted that manufacturers utilizing 5-axis technology reported a 30% decrease in production time due to reduced setups and the ability to machine complex parts more quickly. Coupled with advanced CAD/CAM software, these machines empower engineers and designers to push the boundaries of what's possible, producing components that would have been impractical or impossible with less sophisticated manufacturing methods. As a result, companies can respond more adeptly to market demands, shorten lead times, and ultimately enhance their competitive edge.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Enhanced Design Flexibility | Allows for complex geometries and intricate shapes that are difficult to achieve with traditional machines. | Enables innovation in product design and engineering. |

| Reduced Setup Time | Machining multiple sides of a part in one operation decreases the need for repositioning. | Improves efficiency and reduces lead time. |

| Improved Accuracy | Minimizes human error and part misalignment, ensuring higher precision in machining. | Leads to better quality products and lower rejection rates. |

| Increased Efficiency | Multi-axis machines can cut and mill simultaneously, enhancing productivity. | Maximizes production output and reduces manufacturing costs. |

| Versatility | Can handle a diverse range of materials and processes, including milling, drilling, and grinding. | Offers greater adaptability to various production requirements. |

| Reduced Waste | Optimized material usage through precise cutting techniques reduces scrap material. | Lowers material costs and supports sustainability efforts. |

| Greater Tool Life | Improved cutting conditions lead to less wear on tools, extending their lifespan. | Reduces tooling costs and downtime for tool changes. |

| Enhanced Surface Finish | Achieves superior surface quality with less post-processing needed. | Improves overall product aesthetics and functionality. |

| Simplified Processes | Reduces the need for multiple machines by performing various operations in one setup. | Streamlines production and simplifies workflow management. |

The integration of 5-axis machines in modern manufacturing processes significantly enhances efficiency and minimizes production time. Traditional machining often involves multiple setups and tool changes, which can be time-consuming and prone to errors. However, with 5-axis technology, manufacturers can perform complex operations in a single setup. This capability allows for higher precision and accuracy, reducing the need for rework and additional handling, ultimately streamlining the overall workflow.

Moreover, the advanced flexibility of 5-axis machining enables the production of intricate parts that were previously difficult or impossible to create with traditional methods. This versatility means that manufacturers can respond more quickly to changing demands and custom orders without substantial delays. As a result, companies are not only able to boost their output but also maintain high-quality standards, ensuring that they can meet market needs efficiently while optimizing their resource utilization.

The integration of 5-axis machines in modern manufacturing has significantly transformed the landscape of production, particularly through cost-effectiveness achieved by minimizing material waste and reducing tooling needs. These machines allow for simultaneous movement along multiple axes, which translates into higher precision and efficiency. By being able to perform complex cuts in a single setup, manufacturers can optimize raw material utilization, thereby ensuring that less scrap is generated during the machining process.

Tips for maximizing cost-effectiveness with 5-axis machines include regularly reviewing design files to identify potential waste areas. Using advanced CAD/CAM software can help in visualizing and optimizing the machining process before physical production begins. Additionally, ensuring that tooling is selected wisely, based on the specific demands of each task, can further cut costs by prolonging tool life and reducing the frequency of replacements.

Moreover, embracing advanced simulation technologies provides a deeper understanding of the machining process, facilitating adjustments to programming and tooling that directly impact material efficiency. By incorporating these strategies, manufacturers can not only reduce costs but also improve overall production timelines, allowing for a more agile response to market demands.

The integration of advanced technology in 5-axis machines has revolutionized modern manufacturing, enabling businesses to achieve unprecedented levels of efficiency and precision. These machines utilize sophisticated software and hardware systems that enhance their operational capabilities, allowing for complex geometric designs to be produced with minimal human intervention. By automating processes and reducing the number of setups required, manufacturers can significantly streamline their operations, resulting in faster production times and lower labor costs.

Tips: To optimize the benefits of 5-axis machining, ensure regular maintenance and calibration of your equipment. This not only extends the lifespan of your machinery but also enhances its accuracy, ensuring that every cut and detail meets stringent quality standards. Additionally, invest in training for your staff to familiarize them with the advanced technologies at play, thus improving workflow and minimizing errors.

Furthermore, leveraging integrated software solutions can enhance real-time monitoring and data analysis during the manufacturing process. This technology allows manufacturers to track performance metrics and make informed adjustments on the fly, leading to better resource allocation and reduced waste. By adopting such innovations, organizations can remain competitive and responsive to market demands, ultimately driving growth and profitability.