In the rapidly evolving landscape of modern manufacturing, 5 Axis Machines have emerged as a game-changer. According to a report from Technologies for Advanced Manufacturing, the adoption of 5 Axis machines has increased productivity by over 30% in various sectors. These machines allow for complex geometries and reduced cycle times, making them invaluable in industries such as aerospace and medical devices.

Expert John Richardson highlights the significance of this technology, stating, “The precision offered by 5 Axis Machines can redefine manufacturing capabilities.” This statement underscores the transformative potential of these machines, yet challenges remain. High initial costs and technical complexities can hinder accessibility for smaller manufacturers.

As the industry adapts, manufacturers must assess the balance between investment and long-term gains. 5 Axis Machines are not just tools; they represent a shift in how we approach production. The benefits are profound, yet the journey demands careful consideration and strategic planning.

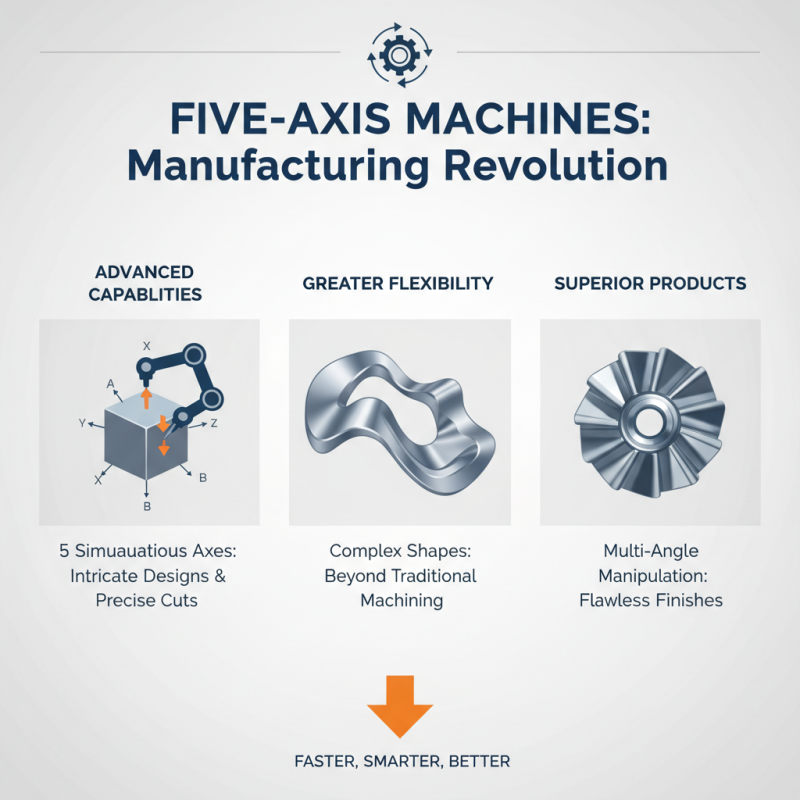

5-axis machines revolutionize modern manufacturing with their advanced capabilities. These machines can move along five different axes simultaneously, allowing for intricate designs and precise cuts. This means greater flexibility in creating complex shapes that would be challenging with traditional machines. The ability to manipulate the material from multiple angles results in superior finished products.

One key feature is the reduction of setup time. With 5-axis machines, users can often complete several operations in one setup. This efficiency can lead to lowered production costs and faster turnaround times. Moreover, these machines enhance accuracy. The precision they offer minimizes human error, crucial for industries requiring exact specifications. However, operating such machines can demand a higher skill level. Operators must understand the software and mechanics deeply, which can be a barrier for some teams.

Despite their advantages, 5-axis machines come with challenges too. Maintenance and training can be costly. Regular calibration is important to ensure that parts are being produced within tolerance limits. Additionally, while they can handle intricate designs, not all materials may be suited for 5-axis machining. This means careful material selection is essential. Balancing these factors in a manufacturing environment is a continuous learning process.

5 axis machines have transformed the realm of manufacturing. They offer enhanced precision and accuracy, especially in complex part production. These machines can move along multiple axes simultaneously. This allows them to create intricate geometries that traditional machines simply cannot achieve.

Imagine crafting a detailed component with tight tolerances. A 5 axis machine achieves this with ease. The ability to angle the part at different orientations enhances tool access. However, setting up such machinery can be challenging. Operators need extensive training to maximize their capabilities. Mistakes during setup can lead to costly errors. Continuous reflection on operational processes is essential.

Precision isn't just about the machine. It involves understanding material behavior and dynamics. The risk of overconfidence in technology can lead to oversight. Engineers must regularly inspect and adjust their work. Even with advanced machines, the human element remains crucial. Balancing technology with skillful oversight sets the stage for true innovation.

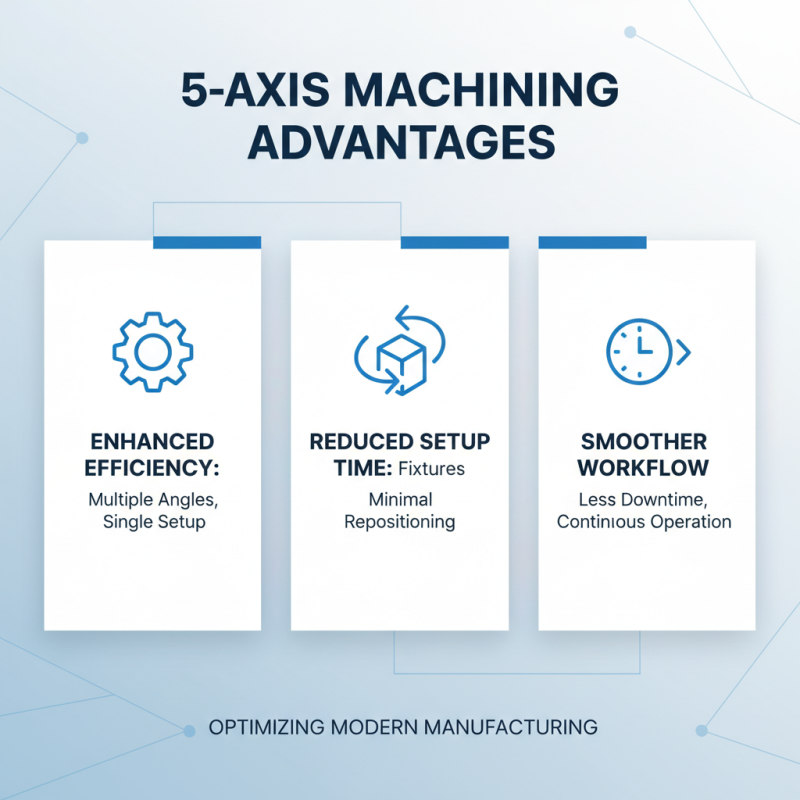

The integration of 5-axis machines in manufacturing presents significant advantages. These machines enhance efficiency by allowing multiple angles of operation in a single setup. Traditional methods often require several fixtures, which can waste time. With 5-axis machines, the need for repositioning is minimized. This leads to less downtime and smoother workflows.

Reduced production time is a noteworthy outcome of using these advanced machines. They allow for complex parts to be machined quickly and accurately. For example, creating intricate components typically involves labor-intensive processes. However, a 5-axis machine can achieve this in fewer steps. The precision reduces the chances of errors. Yet, some users may struggle with setup and programming. It's essential to invest in operator training to maximize productivity.

Despite the clear benefits, challenges exist. Not every shop is ready for the transition. Maintenance and initial costs can be barriers. Organizations might find it hard to adapt fully. Reflecting on these hurdles is crucial for strategic planning in manufacturing. Embracing innovation is vital, but recognizing the need for gradual improvement is equally important.

5-axis machines have transformed modern manufacturing with their exceptional versatility. These machines can work with various materials, including metals, plastics, and composites. By using advanced tool paths, they produce intricate parts that traditional machines struggle to create. This adaptability opens doors for industries, from aerospace to medical devices.

When choosing materials for 5-axis machining, consider their properties. Softer materials can be processed faster but may lack precision. Harder materials are durable but can challenge machine tools and require more time. Balance between quality and processing speed is essential.

Tip: Regularly evaluate the capabilities of your 5-axis machine. Understanding its limits helps prevent costly errors. Also, consider exploring new materials that your machine can handle. This simple step could elevate your production quality and efficiency.

It’s crucial to monitor the wear and tear on tools used in 5-axis machines. Dull tools lead to imperfect finishes and waste material. Keep an eye on maintenance schedules, and do not overlook signs of fatigue in the machine. A small oversight can result in major setbacks. Continually reflect on your processes and adapt to improve workflow.

The integration of 5-axis machines in modern manufacturing offers substantial cost-effectiveness. These machines allow complex parts to be produced in fewer setups. This reduces labor hours and increases efficiency. High precision results in less waste, optimizing material usage. In a competitive market, every cent counts. Companies can save significantly on production costs.

Investing in 5-axis technology may seem daunting initially. However, the long-term investment benefits are compelling. Maintenance costs are lower due to fewer moving parts. The longevity of these machines often exceeds that of traditional setups. Skilled operators can produce intricate designs quickly. While training is necessary, the payoff can be immense.

Reflecting on potential drawbacks is essential. The upfront cost is a barrier for many smaller manufacturers. It requires a commitment to embracing advanced technology. Transitioning to a 5-axis setup isn't always smooth. Yet, for those willing to invest, the returns can significantly enhance their production capabilities.