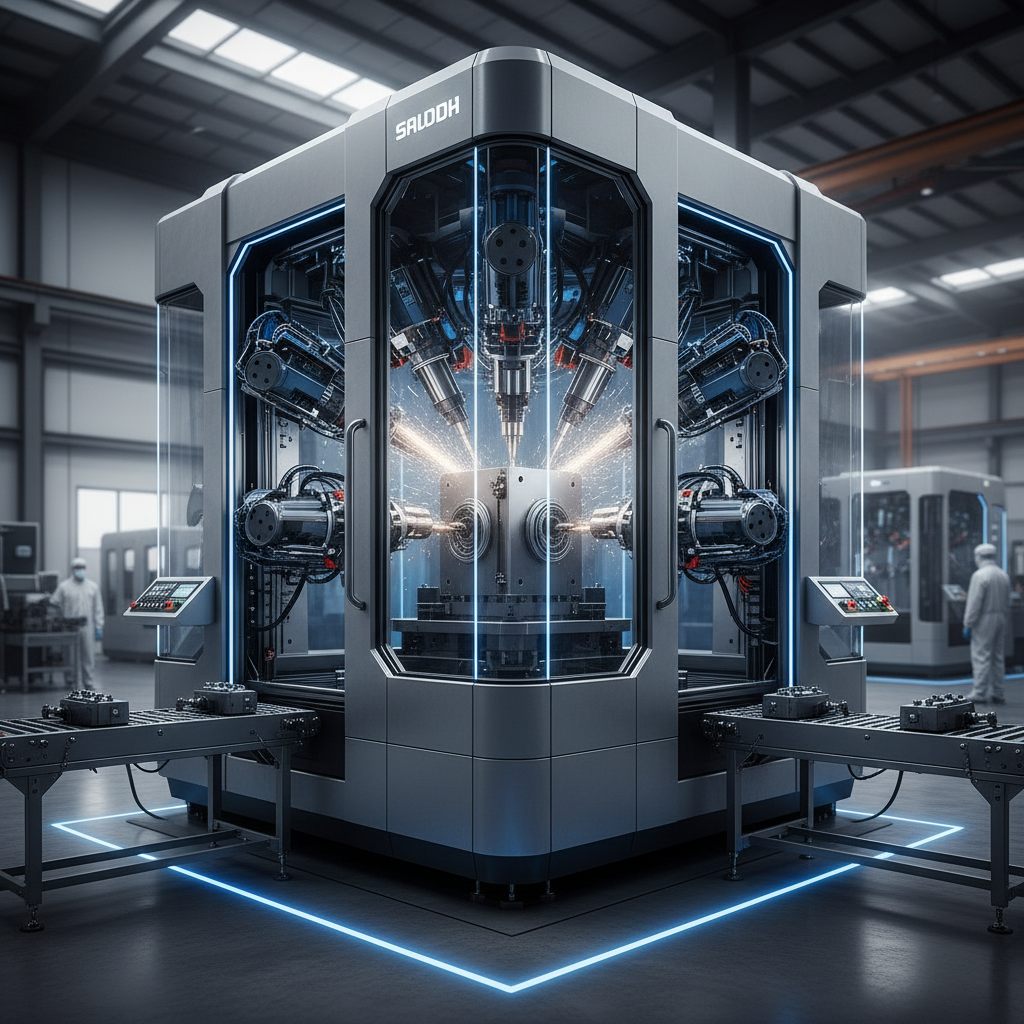

In the ever-evolving landscape of manufacturing and production, the integration of advanced machinery is pivotal for enhancing operational efficiency. Among the various innovations, the Six-Sided Drilling Machine stands out as a game-changer. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.08 billion by 2025, driven by the demand for precision and speed in production processes. The Six-Sided Drilling Machine exemplifies this trend, enabling manufacturers to achieve higher levels of output with significantly reduced lead times.

Utilizing the Six-Sided Drilling Machine not only streamlines the drilling and machining processes but also enhances overall productivity. With the capability to drill on multiple sides of a workpiece simultaneously, manufacturers can reduce setup times while increasing the accuracy of each operation. A study from the American Society of Mechanical Engineers indicates that organizations that adopt advanced drilling technologies can expect up to a 30% reduction in production time and a corresponding decrease in operational costs. This efficiency translates into improved profit margins and competitive advantage in the market, making the Six-Sided Drilling Machine an essential investment for forward-thinking manufacturers aiming to optimize their production lines.

Reduction of Material Waste: Optimizing Resources with Six-Sided Machines

| Benefit | Description | Impact on Production | Additional Notes |

|---|---|---|---|

| Increased Precision | Allows for highly accurate drilling with minimal deviation. | Reduces material waste and increases product quality. | Key for industries requiring tight tolerances. |

| Efficiency | Faster drilling times compared to traditional methods. | Increases throughput and productivity per hour. | Benefits are amplified in high-volume production. |

| Versatility | Can handle multiple types of materials and drilling tasks. | Suitable for a variety of industries and applications. | Reduces the need for multiple machines. |

| Reduced Labor Costs | Automation reduces the number of operators needed. | Lower overall labor expenses. | Advancements in machine programming support ease of use. |

| Safety Features | Modern machines come with enhanced safety protocols. | Lower risk of accidents in the workplace. | Important for compliance with industry standards. |

| Cost-Effectiveness | Long-term savings due to reduced material waste and labor. | Improved ROI on machinery investments. | Initial investment offset by ongoing savings. |

| Enhanced Flexibility | Adaptable to different project sizes and specifications. | Can quickly switch between tasks as needed. | Supports rapid prototyping and design changes. |

| Minimized Downtime | Less frequent maintenance and smoother operation. | Increased operational hours without interruptions. | Benefits long-term production schedules. |

| Data Integration | Can be easily integrated with other technologies and systems. | Streamlined operations and data tracking. | Facilitates Industry 4.0 implementations. |

The use of six-sided drilling machines has revolutionized the manufacturing landscape, particularly in enhancing production speed. According to a report by the National Institute of Standards and Technology (NIST), manufacturers that utilize advanced drilling technology have reported efficiency gains of up to 30%. This increase is attributed to the ability of six-sided machines to execute multiple operations simultaneously, significantly reducing cycle times while maintaining high precision.

One valuable tip for manufacturers considering the switch to a six-sided drilling machine is to invest in appropriate training for operators. Proper training can leverage the full potential of the machinery, ensuring that the workforce is adept at both setup and operation. Additionally, integrating automated material handling systems can further optimize production flow, aligning perfectly with the enhanced capabilities of six-sided drilling machines.

Furthermore, maintaining regular equipment upgrades is crucial. According to a 2022 report from the Machinery Manufacturers Association, businesses that conducted routine maintenance and upgrades on their drilling machines saw a 20% decrease in downtime. By staying current with technology, manufacturers can maximize the efficiency benefits provided by these machines, ultimately leading to a more productive and cost-effective operation.

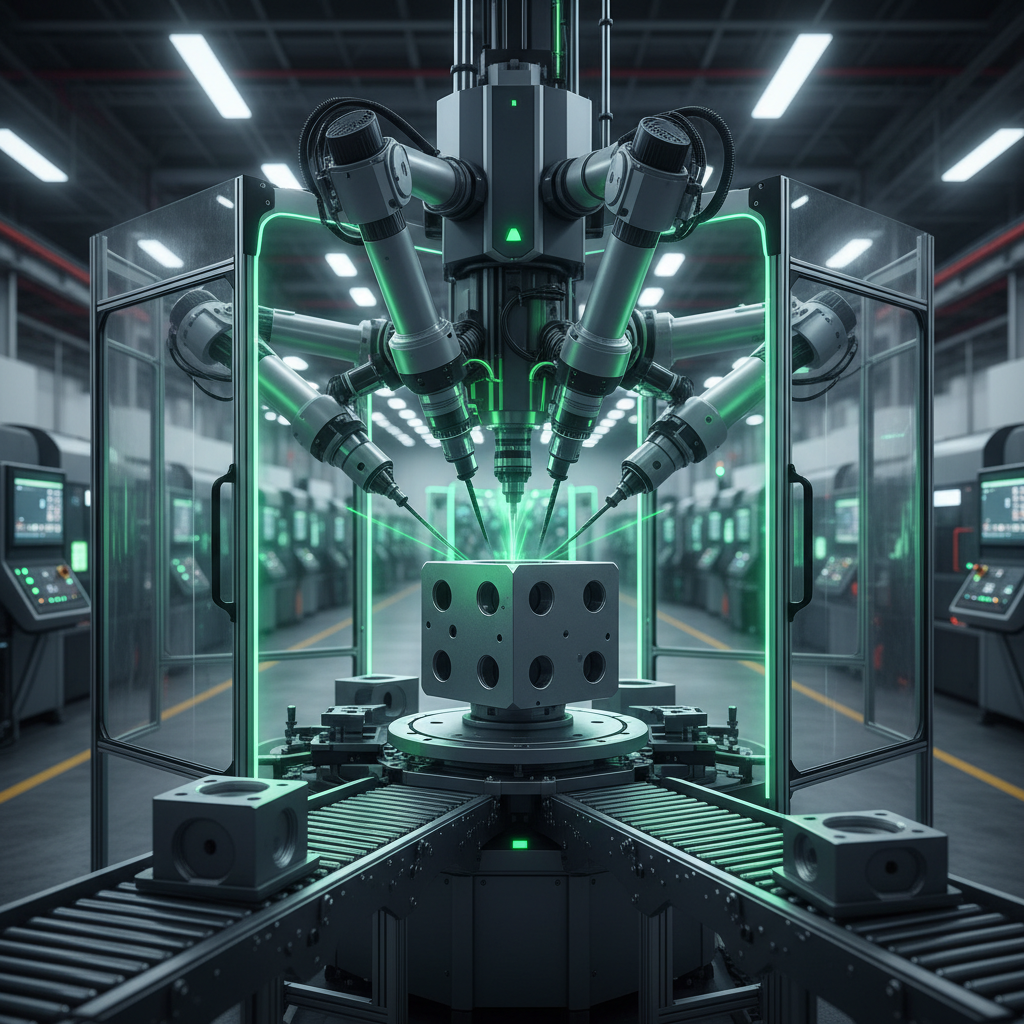

The six-sided drilling machine stands out for its remarkable versatility in various applications, making it an invaluable asset in modern manufacturing. Unlike traditional single-sided drilling equipment, this advanced machine allows for simultaneous drilling on multiple faces of a workpiece, significantly increasing productivity while reducing manual labor. This ability to perform several operations at once not only streamlines workflow but also ensures a higher level of precision, which is crucial in industries like aerospace and automotive.

Furthermore, the adaptability of the six-sided drilling machine extends beyond its basic functions. It can be configured to accommodate a wide range of materials and designs, catering to diverse production needs. Whether it's creating intricate components or large parts, this equipment can handle it all with ease. The versatility also means that manufacturers can transition seamlessly between projects, minimizing downtime and enhancing overall operational efficiency. In a fast-paced market where agility is key, the six-sided drilling machine is a game-changer that empowers businesses to meet customer demands promptly and effectively.

The transition to six-sided drilling technology has been a game-changer for manufacturers seeking cost-effectiveness in their production processes. According to a report by the Manufacturing Institute, companies that adopt advanced drilling technologies can reduce production costs by up to 20%. This significant savings stems from the increased efficiency and versatility of six-sided drilling machines, which allow for simultaneous operations on multiple sides of a workpiece, minimizing cycle times and labor costs.

Furthermore, a study published by the International Journal of Advanced Manufacturing Technology highlights that six-sided drilling machines not only cut down on operational expenditures but also extend the lifespan of tooling. This longevity translates to lower maintenance costs and fewer replacements, maximizing the return on investment for manufacturers. By optimizing resource usage and reducing waste, companies can achieve an estimated additional savings of 15% annually, reinforcing the value of six-sided drilling technology in today’s competitive manufacturing landscape.

重要信息提示

在进行图文内容排版时,请确保所有必要的信息和图片均被包含。

这里是一些与图片相关说明的文字。特别注意:确保所有图像的质量清晰。

在排版时,请考虑内容的整体美观和易读性,特别是对移动端用户。

总结要点

请确保内容有条理、重点突出,并保持一致的格式。