Choosing the best CNC router for your woodworking projects is pivotal in achieving precision and efficiency. According to a recent report by the Industry Association of CNC Technologies, the global CNC router market is expected to grow at a CAGR of 4.5% from 2021 to 2028, underscoring the increasing reliance on CNC technology in various sectors, including woodworking. With numerous options available, it becomes essential for woodworkers to identify machinery that not only meets their operational needs but also enhances their creative capabilities.

As noted by industry expert Michael Chen, founder of Excitech CNC Router, “Selecting the right CNC router is not just about the machine; it's about how it fits into your workflow and elevates your projects.” This statement emphasizes the importance of compatibility between the CNC router and the user's specific requirements. Proper assessment of features such as cutting area, spindle power, and software compatibility can significantly impact the outcome of woodworking endeavors. Understanding these elements helps in making an informed decision that aligns with both the project's scope and the woodworker's individual vision.

When selecting the best CNC router for woodworking projects, it's essential to understand the different types available on the market, as each serves unique purposes and design specifications. The most common types include hobbyist routers, professional-grade machines, and industrial routers. Hobbyist routers are typically compact and user-friendly, making them ideal for beginners or those working on smaller-scale projects. They often have limited cutting depth and power but are perfect for intricate designs and light materials.

In contrast, professional-grade CNC routers offer enhanced features such as faster speeds, more robust construction, and greater cutting capacity. These machines cater to small business owners or serious woodworkers who require precision and durability for more challenging tasks. Lastly, industrial routers are heavy-duty machines designed for mass production. They can handle large sheets of material efficiently and come with advanced software for complex designs. Understanding these differences can help you make an informed decision based on your specific projects, budget, and experience level.

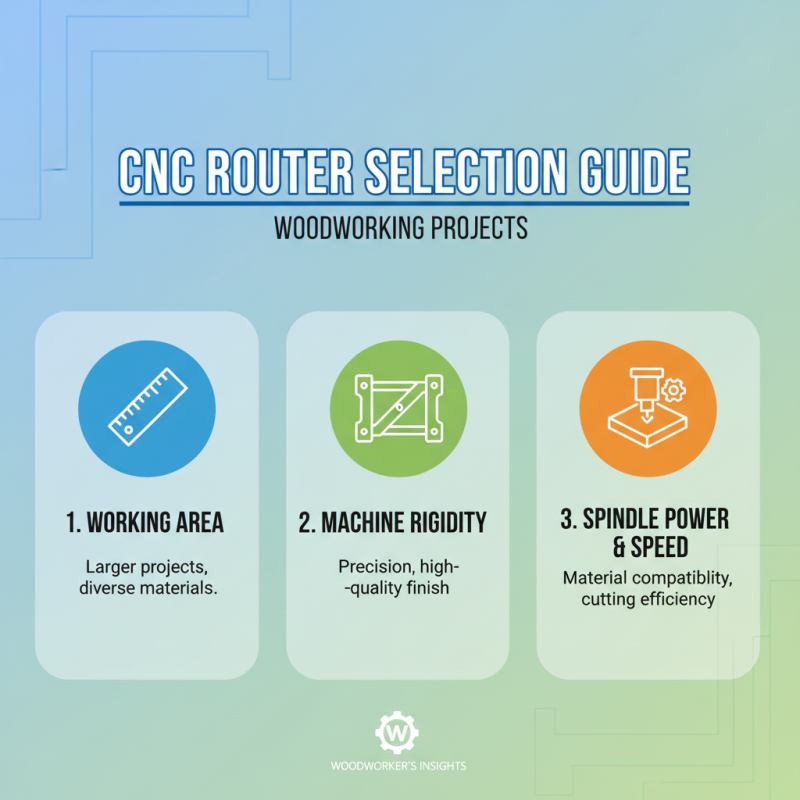

When selecting a CNC router for woodworking projects, several key features are paramount to ensure optimal performance and versatility. First and foremost, consider the size and working area of the router. A larger working area allows for bigger projects and the capacity to handle various materials. Additionally, the machine's rigidity and build quality play critical roles in maintaining precision during operation, which is essential for producing high-quality finished products.

Another significant aspect to evaluate is the spindle power and speed. A powerful spindle can handle tougher materials and deliver smoother cuts, while variable speed settings provide flexibility for different machining processes. Furthermore, the router's software compatibility is vital for design efficiency. A user-friendly interface and compatibility with popular design software can significantly streamline the workflow, making it easier to translate your woodworking ideas into reality. Together, these features contribute to a CNC router's effectiveness in a woodworking shop, enhancing both creativity and productivity.

When selecting the best CNC router for your woodworking projects, it is crucial to assess the specific needs dictated by those projects. Different woodworking tasks require different capabilities from your CNC router. For example, if your projects mainly involve intricate designs or carvings, you will need a router with high precision and a suitable spindle speed to handle detailed work. According to a report from the WPC (Wood Products Coalition), CNC routers that operate at speeds exceeding 24,000 RPM can significantly enhance the quality of detailed cuts, making them ideal for decorative woodworking.

Tip: Always consider the maximum cutting area of the CNC router you intend to buy. If you frequently work on larger projects, ensure your machine can accommodate the size, as this can greatly influence your efficiency.

Moreover, the type of materials you plan to work with should impact your decision. Wood density varies dramatically, and some routers are optimized for softer woods while others excel with hardwoods or composites. Industry data indicates that approximately 65% of woodworking professionals recommend choosing a CNC router with adjustable feed speeds and spindle settings to cater to varying material types.

Tip: Before finalizing your CNC router, examine your woodworking workload — whether you’ll be primarily creating signs, furniture, or intricate artistic designs, this will guide you toward the specifications that best match your intended applications.

This chart represents the suitability of various CNC router types for different woodworking project needs, based on factors like precision, material handling, and ease of use.

When considering the purchase of a CNC router for woodworking projects, budget is a critical factor that can significantly influence your decision. According to a recent industry report, the price range for CNC routers varies widely, from entry-level models costing around $1,000 to advanced systems exceeding $10,000. Understanding your specific needs and how much you are willing to invest will help streamline your options. It is essential to balance your requirements with the features provided by different models, ensuring that you do not overspend on unnecessary capabilities.

When budgeting for a CNC router, it's important to account for additional costs that come with ownership. Apart from the initial purchase price, expenses such as software, maintenance, and accessories like bits and tools can add up quickly. A survey conducted by the Woodworking Machinery Industry Association indicated that owners often overlook these ancillary costs, typically amounting to 20-30% of the router's price over time. Therefore, consider setting aside extra funds for these essentials to avoid unexpected financial strain.

Tips: Assess your woodworking needs: Determine the types of projects you’ll undertake and select a model that caters specifically to those requirements. Prioritize features based on your skill level and project complexity to avoid paying for capabilities you may not use. Additionally, explore financing options or warranties that can make purchasing more manageable without overextending your budget.

| Feature | Entry-Level CNC Router | Mid-Range CNC Router | High-End CNC Router |

|---|---|---|---|

| Price Range | $500 - $1,500 | $1,500 - $4,000 | $4,000 - $10,000 |

| Cutting Area (mm) | 300 x 400 | 600 x 900 | 1200 x 2400 |

| Max Spindle Speed (RPM) | 20,000 | 24,000 | 30,000 |

| Software Compatibility | Basic CAD/CAM | Advanced CAD/CAM | Professional CAD/CAM |

| Material Types | Softwood, MDF | Hardwood, Plastics | Metals, Composites |

To ensure the longevity and performance of your CNC router, regular maintenance is crucial. One of the primary aspects of maintenance involves keeping the machine clean. Dust and debris can accumulate during use, leading to less efficient operation and potential wear on components. After each project, dedicate some time to wipe down the surfaces, especially around the spindle and the guide rails. This not only helps to maintain the aesthetic of your router but also ensures that moving parts are not obstructed, leading to smoother operations.

Lubrication is another key factor in CNC router maintenance. Many routers come with bearings and linear guides that require periodic lubrication to minimize friction and wear. Use a suitable lubricant based on the manufacturer's guidelines to keep these parts functioning optimally. Additionally, inspect belts and pulleys for any signs of wear and replace them as needed to avoid disruptions during your woodworking projects. Regularly checking and tightening loose screws and bolts can also prevent mechanical issues, ensuring that your CNC router operates reliably for years to come. With proper care and attention, you can enhance the performance and lifespan of your machine significantly.