The modern manufacturing landscape is rapidly evolving, influenced by advancements in technology and shifts in industry demands. As manufacturers strive for efficiency, precision, and adaptability, the right machinery becomes pivotal. Among the various tools available, 3-Axis Machines have gained prominence due to their versatility and capability to handle a wide range of machining operations. Whether it’s for milling, drilling, or cutting, selecting the appropriate 3-Axis Machine tailored to specific manufacturing needs can significantly enhance productivity and quality.

As we look towards 2025, the landscape of 3-axis machine tools is significantly influenced by emerging industry trends, particularly in automation and sustainability. According to a study by Custom Market Insights, the global CNC machine market is expected to surge from $101.22 billion in 2025 to $195.59 billion by 2032, growing at a compound annual growth rate (CAGR) of 9.9%. This rapid growth underscores the increasing demand for efficiency and precision in manufacturing processes, aligning with the broader movement towards digitalization and modularization in the industry.

Moreover, the ongoing evolution of automation is critical as manufacturers strive to streamline operations and reduce waste. The principle of the circular economy is gaining traction, encouraging the adoption of technologies that not only enhance productivity but also promote sustainable practices. With innovations in artificial intelligence and smart manufacturing, companies are better equipped to adapt to these changes. As the industry converges towards these trends, choosing the right 3-axis machines tailored to specific manufacturing needs becomes essential for capitalizing on future opportunities and maintaining competitive advantage.

When selecting the right 3-axis machines for manufacturing, evaluating key performance indicators (KPIs) is essential. One crucial KPI to consider is the machine's accuracy and precision, which are pivotal for maintaining product quality. According to a report by Technavio, the demand for high-precision machining is expected to grow by over 5% annually through 2025, driven by industries such as aerospace and automotive that prioritize stringent quality standards.

Additionally, another important KPI is the machine's operational efficiency, which includes factors like cycle time and energy consumption. A study from Market Research Future highlights that manufacturers are increasingly focused on reducing production costs by enhancing the efficiency of their machinery. Machines that have shorter cycle times and lower energy requirements not only contribute to cost savings but also align with the growing trend towards sustainable manufacturing practices.

Lastly, compatibility with automation technologies is becoming a vital consideration as industries embrace Industry 4.0. According to a report by Deloitte, over 70% of manufacturers are investing in automation to improve productivity and adaptability. Hence, evaluating how a 3-axis machine integrates with automation systems should be a critical KPI for any manufacturer looking to future-proof their operations.

The manufacturing landscape is rapidly transforming, driven by advancements in automation technology. By 2025, the global market for machine tools is projected to grow to $132.63 billion, with a robust compound annual growth rate (CAGR) of 8.1% through 2032. This surge signals the increasing reliance on sophisticated equipment such as 3-axis machines, which can significantly enhance efficiency and precision in production processes.

As the adoption of automation accelerates, it is crucial to understand its implications for machine efficiency. Reports indicate that the global laser welding robot market will reach $150 million by 2025, expanding to $520 million by 2035, with a CAGR of 13.7%. In sectors like electric vehicle manufacturing, where welding quality can affect overall product performance, choosing the right automated solutions has become essential.

**Tips:** When selecting a 3-axis machine, consider the specific automation needs of your production line. Evaluate integration capabilities with existing systems and prioritize machines that offer real-time data analytics. Additionally, review vendor performance history to ensure reliability and support, particularly as automation technologies continue to evolve.

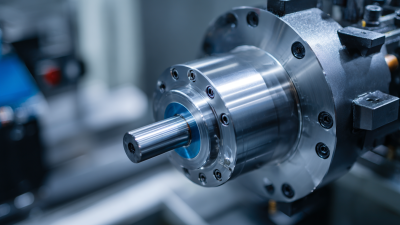

When selecting the appropriate 3-axis machine for your manufacturing needs, evaluating material compatibility is paramount. Different manufacturing sectors utilize a wide variety of materials, each with distinct properties that influence the choice of machinery. For instance, softer materials like plastics can be efficiently machined with high-speed routers, while harder materials like metals necessitate machines equipped with robust spindle designs and specialized tooling. Understanding the specific materials your operations will require allows for a more tailored selection of machinery, ensuring optimal processing and minimal wear over time.

Precision requirements also play a crucial role in the decision-making process for 3-axis machinery. Industries that demand tight tolerances and intricate designs, such as aerospace and medical device manufacturing, benefit from advanced machines equipped with high-resolution encoders and sophisticated control systems. These machines provide the accuracy needed for complex geometries and critical applications, making them indispensable. Conversely, industries focusing on bulk production may prioritize speed and efficiency over minute precision. By aligning your precision requirements with the capabilities of different 3-axis machines, you can enhance production quality while maintaining competitive manufacturing practices.

Precision requirements also play a crucial role in the decision-making process for 3-axis machinery. Industries that demand tight tolerances and intricate designs, such as aerospace and medical device manufacturing, benefit from advanced machines equipped with high-resolution encoders and sophisticated control systems. These machines provide the accuracy needed for complex geometries and critical applications, making them indispensable. Conversely, industries focusing on bulk production may prioritize speed and efficiency over minute precision. By aligning your precision requirements with the capabilities of different 3-axis machines, you can enhance production quality while maintaining competitive manufacturing practices.

As manufacturing industries evolve, investing in 3-axis machines that align with future trends is paramount. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117 billion by 2026, growing at a CAGR of 7.2%. This highlights the rising demand for advanced machining technologies that can enhance productivity and adapt to the shifting landscape of manufacturing. Companies are now prioritizing machines that offer flexibility and precision, ensuring they remain competitive as industry standards escalate.

To ensure you are future-proofing your manufacturing operations, consider these tips: First, evaluate the specific needs of your industry—whether it’s automotive, aerospace, or electronics. These sectors are increasingly relying on automation and smart manufacturing technologies. Second, assess the machine's compatibility with Industry 4.0 advancements. Investing in machines that can integrate IoT capabilities will not only streamline operations but also provide valuable data analytics for decision-making.

Finally, prioritize machines with robust customer support and upgrade options. A study by the International Federation of Robotics indicates that manufacturers who adopt collaborative robotics alongside traditional machines see productivity improvements of up to 20%. Choosing the right 3-axis machines today will secure your operational efficiency tomorrow.