When choosing the best 5-Axis Machines for your manufacturing needs, several factors come into play. These advanced machines enhance productivity and precision. However, selecting the ideal machine can be overwhelming. Each type offers distinct advantages and potential drawbacks.

Understanding your specific applications is crucial. Different industries may require unique features from 5-Axis Machines. For complex parts, a machine with a high degree of rotational flexibility might be necessary. Evaluate your budget as well. Higher precision often comes at a premium price, which not everyone can afford.

While the benefits of 5-Axis Machines are significant, they also come with challenges. The learning curve can be steep. Training staff might require extra time and resources. You must reflect on whether your team is ready for this transition. Careful consideration of these aspects can lead to a more informed decision.

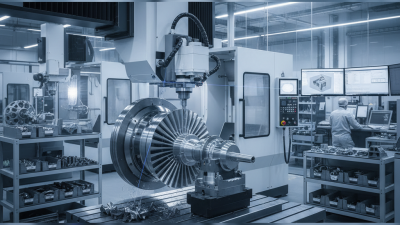

5 axis machines play a crucial role in modern manufacturing. Their ability to perform complex tasks is unmatched. With the capacity to move a tool across five different axes, these machines create intricate parts with high precision. This versatility reduces the need for multiple setups and tools, saving time and costs.

However, choosing the right machine isn't straightforward. Manufacturers need to consider different factors such as size, power, and the type of materials they work with. A complex machine may not always be the best choice. Sometimes, simpler machines might suffice for basic tasks, minimizing expenses.

Moreover, the steep learning curve can be daunting. Operators may struggle to master new software and techniques. Machines can be expensive to maintain too. This reality prompts many to reassess their needs. Will a 5 axis machine enhance efficiency, or will it become a burden? Balancing technology and practicality is essential in making the right decision.

When selecting a 5 axis CNC machine, several key factors come into play. First, consider the machine's workspace. It should accommodate the size of parts you plan to manufacture. A limited workspace can restrict your production capabilities. Pay attention to the travel distances in the X, Y, and Z axes. These dimensions are crucial for achieving precise cuts and successful project outcomes.

Another important aspect is the machine's spindle speed and power. Higher spindle speeds can enhance productivity, especially when working with hard materials. Evaluate your typical materials to determine the required power. A mismatch can lead to inefficient machining or damage to the machine.

Tips: Always verify the machine’s accuracy. Ask for tolerance specifications. Look for user feedback on reliability. You might find hidden issues. It’s wise to think about after-sales support too. Poor support can lead to prolonged downtimes.

Current technology trends also matter. Machines equipped with advanced control systems often provide better user experience. However, high-tech options can be expensive and daunting for some operators. Weigh the costs against potential productivity gains before choosing.

| Factor | Description | Importance Level (1-5) |

|---|---|---|

| Work Envelope | Size of materials the machine can handle. | 5 |

| Spindle Speed | Maximum speed of the spindle for cutting. | 4 |

| Control System | Type of software and user interface used. | 5 |

| Accuracy & Precision | Capability to meet tight tolerances. | 5 |

| Price | Total cost including installation and support. | 3 |

| Tooling Compatibility | Compatibility with various tooling options. | 4 |

| After-Sales Support | Quality of support and maintenance services. | 4 |

| Brand Reputation | Established history and customer satisfaction. | 3 |

When investing in 5 axis machines, understanding the cost versus performance is crucial. Many manufacturers see a return on investment (ROI) based on speed and precision. A report by TechNavio highlights that productivity can increase by up to 30% with advanced machines. However, the initial cost can be substantial, ranging from $100,000 to over $500,000. This upfront cost requires careful analysis.

ROI calculations should focus on cycle time reduction and scrap rate improvement. A study from the National Institute of Standards and Technology shows that reducing cycle time by just 10% can lead to a 20% increase in productivity. Yet, choosing a machine solely based on specs might overlook how well it fits specific tasks. Understanding your unique manufacturing needs is vital.

Many companies find themselves needing to reassess their choices after a purchase. A machine may promise high performance but fail to meet operational demands. It's crucial to evaluate long-term maintenance costs and support. This aspect can impact ROI significantly. A thoughtful approach to cost versus performance can lead to more informed decisions and ultimately, higher profitability.

This chart illustrates the cost and performance (in RPM) of different 5 axis machines. As manufacturers evaluate their options, understanding the balance between expenditure and operational efficiency is crucial for maximizing ROI.

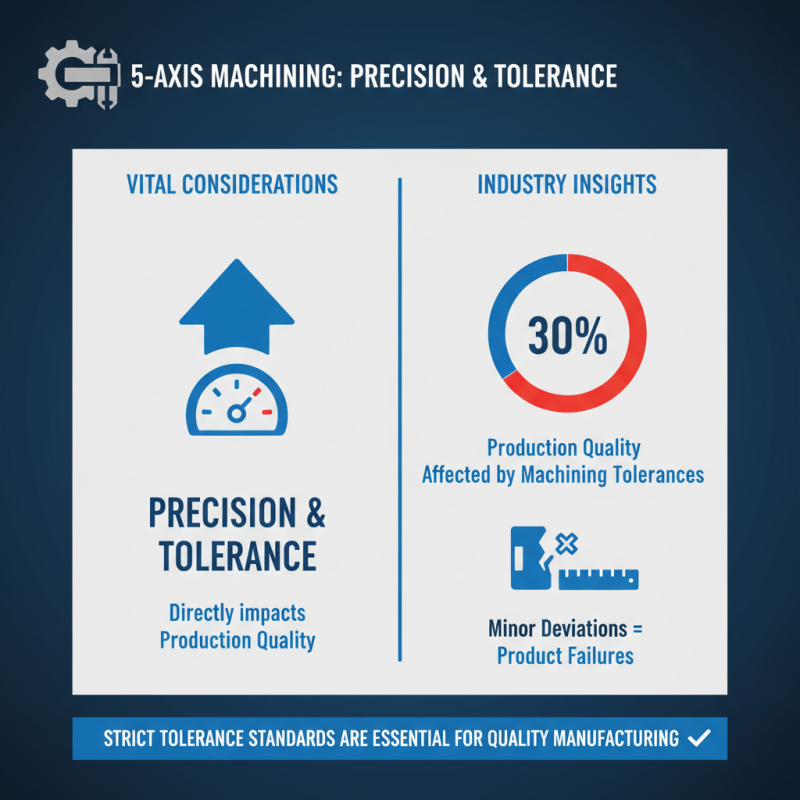

When selecting a 5-axis machining center, precision and tolerance are vital considerations. A recent industry report indicates that machining tolerances can affect production quality by nearly 30%. It's essential to evaluate how strict the tolerance standards are for your specific manufacturing needs. With precision engineering, even minor deviations can lead to product failures.

Most modern 5-axis machines can achieve tolerances within ±0.005 inches. However, tests show that not all machines perform consistently. Some models struggle with maintaining accuracy at larger volumes. This variance can lead to unexpected costs and delays in production. Setting clear, measurable standards for precision helps mitigate these risks.

Analyzing the stability of these machines under varying loads is also crucial. Reports indicate that machines operating under higher stress often show progress in wear and tear faster than expected. Regularly monitoring performance and calibrating settings is not just best practice but a necessity in maintaining operational efficiency. Choosing the right machine demands careful consideration of these precise factors.

The integration of automation and advanced software in 5-axis machining is transforming the manufacturing landscape. According to a recent report from the Tech Industry Research Group, 75% of manufacturers now heavily rely on automated solutions to improve efficiency.

Automation reduces human error and enhances productivity. However, unexpected machine downtime remains a concern. Many manufacturers face challenges in maintaining these automated systems.

Software integration plays a crucial role in optimizing machining processes. The latest advances in CAD/CAM software allow for seamless design-to-manufacture workflows. About 65% of surveyed companies reported increased accuracy and reduced cycle times due to better software tools. Yet, not all firms adapt quickly. Those that lag behind may struggle with outdated systems that hamper their competitiveness.

Choosing the right 5-axis machine involves more than just technical specifications. Companies must also consider software compatibility and automation capabilities. An inappropriate choice can lead to inefficiencies that ripple through production lines. As trends evolve, continuous evaluation of technology is necessary. Learning from past implementations, both successful and not, will guide future investment decisions.