In the evolving landscape of modern manufacturing and construction, the significance of technology cannot be overstated. Among the various tools that have emerged to enhance efficiency and precision in drilling tasks, Automatic Drilling Machines stand out as a crucial addition. These innovative machines not only automate the drilling process but also improve accuracy, increase productivity, and reduce the potential for human error. As we approach 2025, it is vital for professionals across various industries to understand how to select the best Automatic Drilling Machines to meet their project needs.

Choosing the right Automatic Drilling Machines involves a thorough evaluation of various factors, including specifications, capabilities, and the specific requirements of your projects. With advancements in technology, options are increasingly diverse, and understanding these choices is essential for making informed decisions. This guide will provide insights into what to consider when selecting an automatic drilling machine, ensuring your investment aligns with your operational goals. By focusing on the right features and functionality, you can enhance your project outcomes and streamline your workflow for the future.

When selecting the best automatic drilling machines for your projects in 2025, understanding your project requirements is crucial. The ideal automatic drilling machine should align with the specific needs of your tasks, whether it involves high-volume production or intricate design work. Recent industry reports indicate that the global automatic drilling machines market is projected to reach USD 4.2 billion by 2026, with a CAGR of 5.1% from 2021 to 2026. This growth underscores the increasing reliance on precision and efficiency in engineering and manufacturing sectors.

Key considerations in determining your project requirements include the materials you will be drilling, the required precision, and the scale of production. For instance, a machine designed for metalworking may have different specifications compared to one intended for woodworking. According to a report by Technavio, nearly 48% of manufacturers cite productivity increases as a primary driver for adopting advanced drilling technology. Therefore, identifying whether your projects demand faster drilling speeds or the capability to handle various materials will guide you in selecting a machine that enhances your workflow while ensuring quality output.

When selecting the best automatic drilling machines for your projects in 2025, it's essential to pay attention to several key features that can enhance efficiency and ease of use. First, consider the machine's power and torque settings. A higher power output allows for drilling into harder materials, while adjustable torque settings ensure precision and prevent damage to the workpiece. Additionally, look for machines that incorporate advanced motor technologies, as they tend to offer smoother operation and extended durability.

Another crucial aspect is the machine's automation capabilities. Features like programmable settings and integration with computer-aided design (CAD) software can significantly streamline the drilling process. These systems enable users to execute intricate patterns and specifications with minimal manual intervention. Furthermore, ergonomic design and portability should not be overlooked; a comfortable grip and lightweight construction can enhance maneuverability, making it easier to use the machine over extended periods.

Lastly, the availability of interchangeable drill bits and attachments is vital for versatility. A machine that supports a variety of accessories and customization options allows for greater adaptability across different projects. Ensuring compatibility with the latest technologies, such as wireless controls and smart monitoring systems, can also be beneficial in keeping up with industry advancements in 2025.

When selecting the best automatic drilling machines for your projects in 2025, it’s crucial to consider industry-specific performance metrics that align with your operational needs. Various sectors, such as construction, manufacturing, and aerospace, require different functionalities and precision levels in drilling machines. Key performance indicators to evaluate include speed, accuracy, durability, and adaptability to various materials, as these metrics directly influence project timelines and overall quality of work.

For instance, in the construction industry, drilling machines that prioritize robustness and high-speed capability may be essential for handling tough materials like concrete or metal framing. Conversely, for more precision-driven industries like aerospace, machines must offer exceptional accuracy and the ability to perform intricate drilling patterns without compromising material integrity. Moreover, energy efficiency and ease of maintenance also play critical roles in selecting the right machine, as they impact both operational costs and sustainability practices within the industry.

By carefully analyzing these performance metrics, you can ensure that your chosen automatic drilling machine meets the specific requirements of your projects while enhancing productivity and safety.

In 2025, the landscape of automatic drilling machines is set to undergo significant advancements, driven by the integration of artificial intelligence and enhanced automation technologies. Recent industry reports indicate that the global market for automatic drilling equipment is projected to reach $8.5 billion by the end of the year, highlighting a compound annual growth rate (CAGR) of 7.3% from 2021 to 2025. This growth is propelled by demands for increased efficiency, precision, and cost-effectiveness in manufacturing and construction projects.

Leading brands in the automatic drilling market are focusing on innovations such as smart sensors and IoT connectivity. These technological advancements enable machines to perform real-time data analysis, allowing for predictive maintenance and reduced downtime. For instance, automatic drilling machines equipped with advanced robotic systems can operate in complex environments with minimal human intervention, significantly enhancing productivity. Furthermore, the development of eco-friendly drilling solutions that utilize sustainable energy sources is becoming increasingly important, accounting for a notable trend in environmental responsibility within the industry, as revealed in the latest market analyses.

As companies prioritize automation and smart technology, understanding the key features—such as programmable depth control, adaptability to various materials, and user-friendly interfaces—will be essential for selecting the right machine for diverse project requirements. Thus, as we progress into 2025, staying informed about these advancements and the brands leading the charge will be critical for professionals in the field.

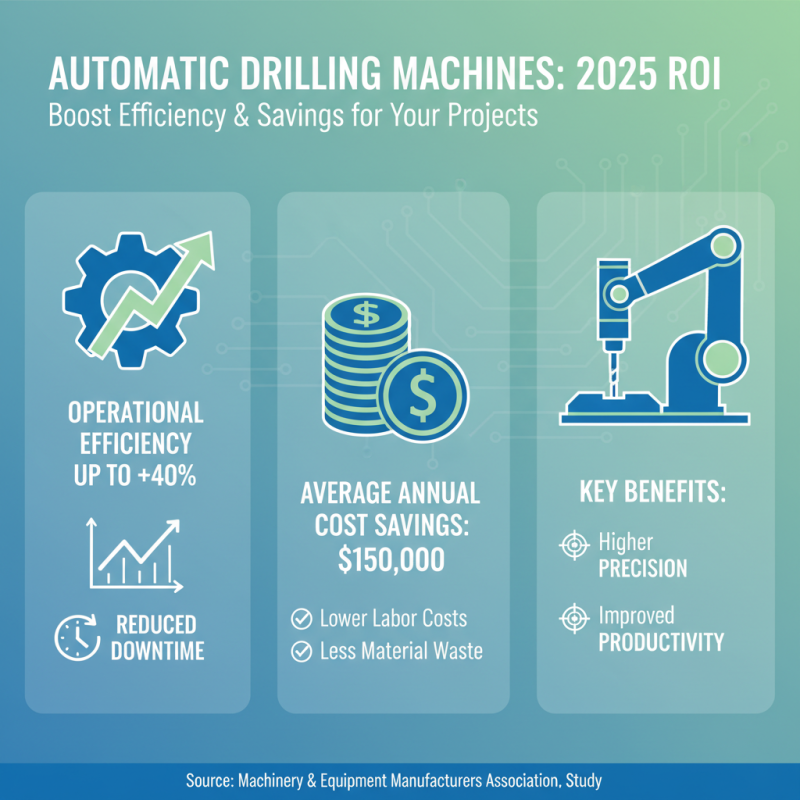

When evaluating the cost-effectiveness of automatic drilling machines for your 2025 projects, it's essential to consider the return on investment (ROI) these machines can offer. Industry reports indicate that automatic drilling systems can increase operational efficiency by up to 40%, significantly reducing labor costs and operational downtime. According to a recent study by the Machinery and Equipment Manufacturers Association, companies that adopted automatic drilling technologies reported an average cost savings of approximately $150,000 annually, predominantly due to higher precision and reduced material waste.

Additionally, the initial investment in automatic drilling machines is often offset by the long-term benefits they bring to production. A comprehensive analysis from the Industrial Automation Consortium highlighted that businesses experience a payback period of less than two years for such machines, with many seeing substantial gains in productivity and quality. Furthermore, automating repetitive tasks allows skilled workers to focus on more complex operations, thus enhancing overall workforce efficiency. This shift not only bolsters project timelines but also elevates the quality of the output, further contributing to a positive ROI.

As you assess your next project needs, weighing the long-term financial implications and productivity improvements afforded by automatic drilling machines will be crucial in making an informed decision that aligns with future industry demands.