Choosing the right 4-Axis Machines for your CNC projects can be challenging. With so many options available, the decision process can feel overwhelming. These machines offer enhanced capabilities compared to traditional 3-axis models. They allow for more complex designs and applications.

When selecting a 4-Axis Machine, consider your specific project needs. Think about the materials you'll be working with. Different machines handle various materials differently. Do you need precision for intricate designs? Or are you focusing on larger, more straightforward parts?

Reflect on your experience level as well. Beginners may find some 4-Axis Machines complex. Training and support can be crucial. Take your time to research the features and specifications that fit your requirements. It may be worthwhile to consult with experts or read user reviews. You want a machine that not only fits your projects but also grows with your skills.

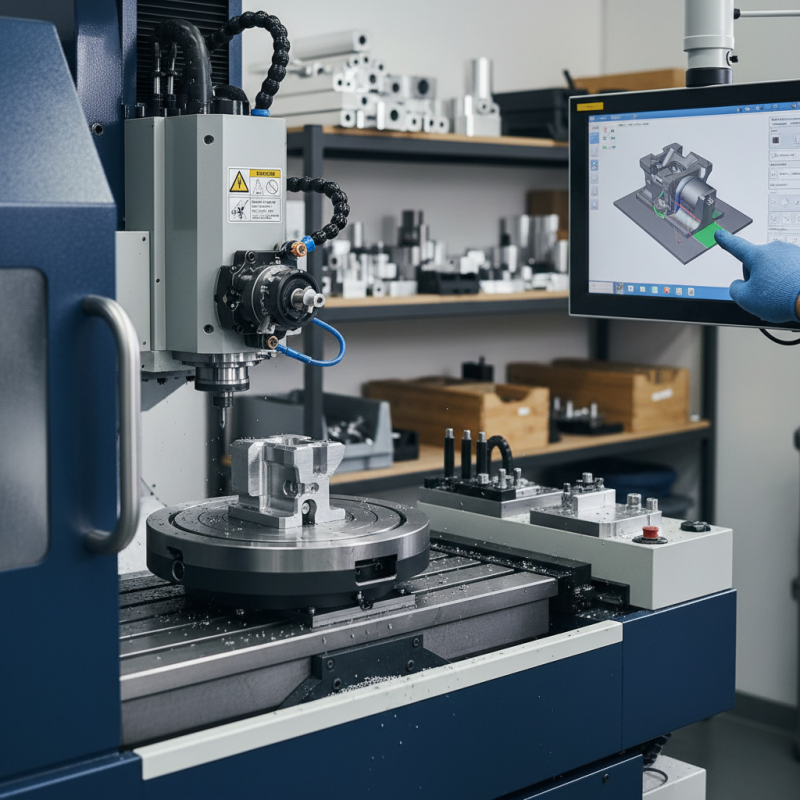

4 Axis CNC machines are crucial in modern fabrication. They enable more complex designs than traditional 3-axis machines. With an additional rotational axis, these machines provide enhanced versatility. Projects can include intricate carvings or complex components. Understanding their mechanics is vital for optimal use.

When selecting a 4-axis machine, consider the types of materials you'll work with. Softer materials may not require the same power as metals or composites. Evaluate whether the machine can handle your expected workload. Look for features that suit your projects but be aware of your budget constraints.

Tips: Always read user reviews and seek feedback from machinists. They can offer practical insights that guide your choice. It's also wise to visit a workshop if possible. Watching a machine in action helps clarify its strengths and weaknesses. Consider starting with a rented or second-hand model before a significant investment. This approach minimizes risk while you learn.

When selecting a 4 axis CNC machine, consider precision as a primary factor. Precision machining is crucial in various industries. According to a report from the International Journal of Advanced Manufacturing Technology, precision components can boost production rates by up to 30%. Ensure the machine can handle the desired material with accurate tolerances.

Evaluating features like rigidity and stability is vital. A robust frame minimizes vibration during cutting, ensuring consistent quality. Look for machines with high-quality ballscrews and linear guides. This can enhance machining accuracy. The spindle speed also matters; higher RPMs allow for faster production cycles. However, overloading the spindle can lead to premature wear.

**Tip:** Consider the machine’s ease of use. A complicated interface can slow down operations. User-friendly controls simplify machining tasks.

Don’t overlook the importance of software compatibility. Integrating advanced CAM software is crucial for optimized operations. Make sure the machine supports the necessary file formats for your projects. Lastly, think about the machine’s maintenance. Regular upkeep can prevent costly downtime.

**Tip:** Research user reviews for real-world insights. Sometimes, specifications don’t tell the full story.

| Feature | Description | Importance Level |

|---|---|---|

| Accuracy | The ability of the machine to produce parts within specified tolerance levels. | High |

| Work Envelope | The maximum size of the material the machine can accommodate. | Medium |

| Speed | The rate at which the machine can operate to produce parts. | High |

| Control System | The software and hardware used to control the CNC operations. | High |

| Tooling Flexibility | The types of tools that can be used with the machine for various operations. | Medium |

| Ease of Use | User-friendly interfaces and setups for operators. | High |

| Maintenance Requirements | Regular maintenance needed to keep the machine running optimally. | Medium |

When considering the cost-effectiveness of 4 axis CNC machines, it's vital to examine various models and their features. A 2022 industry report revealed that the average cost of a 4 axis CNC machine ranges from $40,000 to $100,000. The price often reflects features, such as speed and precision. Adding a fourth axis can enhance capabilities but can also inflate costs.

A crucial detail is the operational costs tied to maintenance and tooling. Research shows that poorly maintained machines can lead to 20% higher production costs over time. Users often overlook these recurring costs. While a low upfront investment may seem attractive, consider long-term expenses. Those might offset initial savings.

Flexibility is another factor. Some models allow for rapid changeovers, reducing downtime. However, cheaper models may lack this feature. A recent study found that businesses that invest wisely often see a return on investment within 1-3 years. Still, some may find themselves regretting their hasty decision due to unforeseen limits. Balancing initial investment and potential growth is critical.

When choosing the right 4 axis machines, industry standards play a crucial role. Hobbyist models often focus on accessibility and affordability. They are suitable for simple projects and prototyping. However, these machines may lack precision for intricate designs. Users might encounter limitations in material choices too. Low-end models can struggle with durability over time.

Industrial 4 axis machines cater to more demanding applications. They offer higher tolerance and robust construction. These machines can handle complex components and diverse materials. Yet, they come with a steeper price tag. Investing in industrial machinery requires careful consideration of project scale. Users should reflect on their actual needs. A hobbyist might not benefit from advanced features, leading to wasted resources.

When considering 4 axis CNC machines, understanding their applications and material compatibility is vital. These machines excel in tasks like engraving, milling, and complex contour cutting. They are popular for creating detailed part designs in industries like aerospace and automotive. Materials such as wood, plastic, aluminum, and some mild steels work well. Knowing the material type can lead to better outcomes.

Tips: Make sure to test different materials. Each material behaves uniquely when cut. It’s important to experiment with various feed rates and spindle speeds. This will help in achieving high-quality finishes without damaging the workpiece.

While 4 axis machines offer great flexibility, they also require precision. Incorrect tool selection or improper setup can lead to poor results. Operators need to be aware of how materials may warp or change during machining. This may affect tolerances and final measurements. Regular calibration and maintenance are essential to keep the machine in optimal condition.