Choosing the right boring machine for your project can be challenging. Experts like Charles McGregor, a leader in the Boring Machines industry, emphasize the importance of making informed choices. He once said, “The right machine can save time and money.” Understanding your project’s needs is essential.

Different boring machines have unique capabilities. Some are designed for deep drilling, while others excel in handling various soil conditions. It’s crucial to assess the site and the specifications required. Do you need a compact model, or is a heavy-duty machine more suitable?

Many factors influence your decision, including budget and project timeline. Often, people underestimate machine capabilities or overestimate their needs. Reflecting on these aspects can prevent costly mistakes. Ultimately, the right choice can significantly enhance productivity and efficiency in your work.

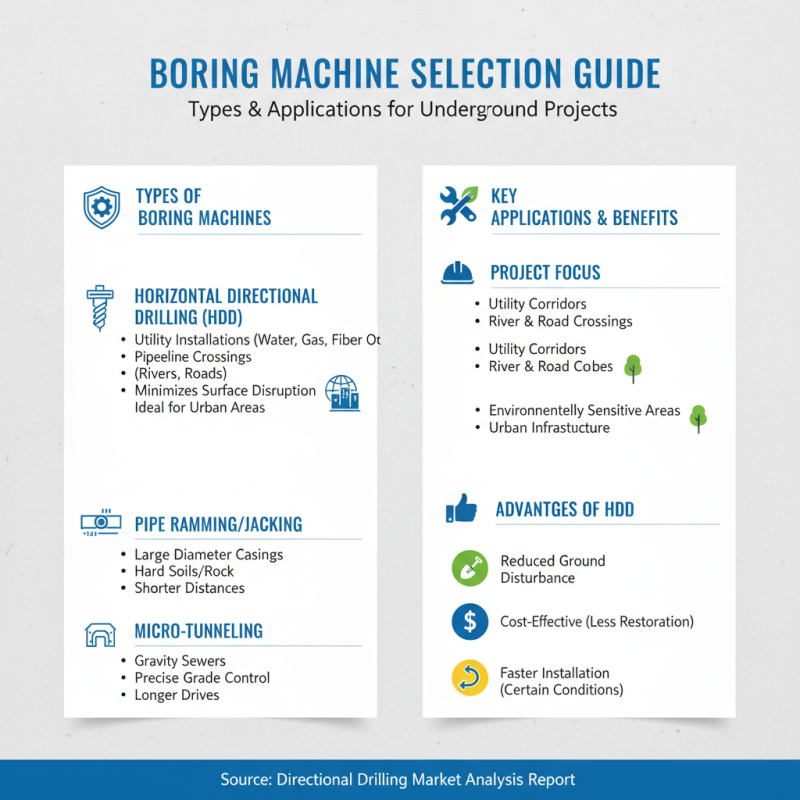

When selecting a boring machine, understanding the types and their applications is crucial. There are several categories that cater to different project needs. Horizontal directional drilling (HDD) is often used for utility installations. This method minimizes surface disruption. It is suitable for urban environments, according to the “Directional Drilling Market Analysis Report.”

Auger boring machines come into play for deeper applications. They work well in tight spaces and can handle various soil conditions. The reports indicate that 40% of projects require deep bore applications. Contractors often face challenges with soil stability and hydraulic pressure. Selecting the right auger setup is vital for avoiding project delays.

Microtunneling machines offer precision for urban infrastructure projects. They create tunnels with minimal surface footprint. Industry studies show a growing demand for microtunneling due to urbanization trends. Yet, these machines can be costly and complex. Evaluating the project scope is essential before committing to this technology. Each boring machine type has its specific advantages. However, understanding the project requirements is fundamental.

Selecting the right boring machine is crucial for project success. Key factors include project size, soil type, and required depth. According to a 2022 industry report, approximately 70% of operators report efficiency issues due to improper machine selection. Understanding project specifics can help avoid these pitfalls.

Soil characteristics play a significant role. For instance, soft soils may require different equipment than rocky terrains. A study revealed that 65% of failed projects were linked to inadequate assessment of soil conditions. It's essential to conduct thorough geotechnical investigations before making a decision.

Additionally, consider the depth and diameter needed. Many operators underestimate these aspects. This oversight can lead to costly delays. An alarming 55% of projects experience time overruns related to equipment inadequacies. Assess the project scope carefully. This ensures that the right machine is chosen for effective performance.

When choosing a boring machine, assessing project requirements is crucial. Understanding the project's scope can dictate which machinery will be most effective. Factors to consider include soil type, depth of bore, and overall project size. For instance, a report from the International Society for Trenchless Technology notes that soil conditions can affect performance by up to 30%. Proper analysis of these aspects is essential.

Project depth often impacts the machine selection significantly. Shallow depths might not require heavy-duty equipment, reducing costs. However, deeper projects may need more robust machinery for efficient operation. A survey by the Boring Industry Association indicated that improperly sized machines can lead to a 25% increase in project time. This risk emphasizes the need for careful evaluation.

Construction projects also encounter unique challenges. Boring through rocky terrain or urban infrastructure demands specialized equipment. A poorly chosen machine can lead to delays and budget overruns. Many project managers overlook these details, which can prove costly. Reflecting on past mistakes can help avoid similar issues in future projects.

When selecting a boring machine, the differences between manual and automated options are crucial. Manual boring machines require skilled operators. This can lead to variability in execution, impacting project consistency. Reports show that manual methods can produce a variance of up to 15% in hole diameter accuracy. This inconsistency can be costly in large projects.

On the other hand, automated boring machines typically offer precision. They often integrate advanced technology, such as CNC systems, to ensure accuracy within 0.1 mm. While the initial investment is higher, they reduce labor costs over time. A recent study indicated that automated machines can complete projects up to 50% faster compared to their manual counterparts. However, reliance on automation comes with its own quirks. Machine breakdowns can halt productivity, creating unexpected delays.

Cost and skill level are not the only factors to consider. The nature of the project also plays a role. For smaller tasks, manual machines may suffice. Yet for larger jobs with strict timelines, automated systems shine. Understanding these nuances is key to making informed choices.

Selecting the right boring machine involves careful budgeting and cost management. A recent industry report highlights that 30% of project failures are due to inadequate planning of equipment costs. To avoid this, it’s essential to factor in not just the purchase price but long-term maintenance expenses. Maintenance can account for up to 15% of a machine's total cost over its lifespan.

Understanding project requirements can help refine equipment choices. If the soil condition is unknown, conducting a soil analysis may save costs later. Additionally, rentals can be a viable option for short-term projects. The industry trend shows that renting equipment can save 20-40% compared to outright purchase in certain scenarios. However, frequent rentals may lead to higher long-term costs.

One must consider the trade-off between quality and affordability. Opting for lower-cost machines may cut initial expenses but could lead to increased downtime. Downtime costs the industry approximately $3 billion annually, as per recent studies. Balancing quality, cost, and project needs is crucial. Not all equipment is ideal for every situation, and this distinction requires reflection. Failure to assess these factors could lead to significant budget overruns.