In today's manufacturing landscape, the CNC router stands out as a powerful tool. According to a 2023 industry report by MarketsandMarkets, the CNC machine market is expected to grow to $117.8 billion by 2026, driven largely by advancements in CNC routers. These machines offer precision and efficiency in a variety of applications.

CNC routers excel in cutting wood, plastics, and metals. They reduce human error and increase production speed. However, not every project is suited for a CNC router. Some users may struggle with software compatibility or initial investment costs. Despite these challenges, the benefits often outweigh the drawbacks.

The versatility of CNC routers makes them ideal for numerous sectors, from woodworking to aerospace. Their ability to create detailed designs helps businesses stand out. However, it is essential to assess if the investment aligns with specific project needs. This thoughtful approach ensures the machine’s capabilities match the intended applications.

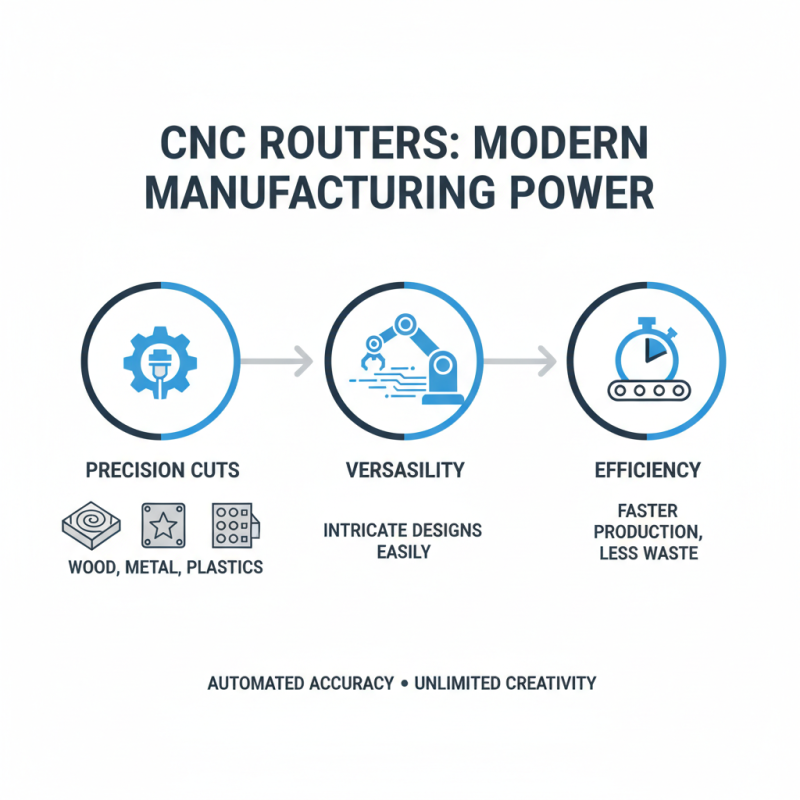

CNC routers are powerful tools used in modern manufacturing. They enable precise cuts and designs in various materials. This includes wood, metal, and plastics. The flexibility of CNC routers allows for intricate patterns that would be difficult by hand.

This technology is based on computer numerical control. A computer program directs the router for each specific task. Operators can create custom designs and replicate them easily. However, achieving the desired results requires skill. Setting up the machine and fine-tuning parameters can be challenging.

Mistakes may occur during the process, leading to material waste. Testing different settings is often necessary. Each project may demand adjustments. This reflects the need for a careful balance between automation and human oversight. Even with advanced technology, human expertise remains vital in maximizing the potential of CNC routers.

CNC routers are revolutionizing the way projects are executed. Their precision is unmatched. Every cut and detail can be replicated with incredible accuracy. This level of precision is essential for intricate designs. A slight miscalculation can derail a project, but CNC routers eliminate this risk. The computer-controlled process ensures that each piece fits perfectly. No more frustration with uneven edges or misaligned components.

Speed is another significant advantage of CNC routers. They can produce parts in a fraction of the time it would take manually. This allows for more projects to be completed faster, boosting productivity. However, it’s essential to balance speed and quality. Rushing can lead to mistakes. Designers must always rethink processes to ensure they are not compromising on quality for the sake of speed.

Consistency in production is another key benefit. With CNC routers, every product is identical. This is crucial for businesses that rely on uniformity. Customers expect the same quality every time. But there’s a challenge here: maintaining that consistency requires diligent attention to detail. Regular maintenance and careful programming are vital. Even small errors in setup can lead to significant variations. Adjusting settings and calibrating machines are tasks that cannot be overlooked.

CNC routers are revolutionizing woodworking and metal fabrication industries. These machines offer precision that hand tools simply cannot match. They cut, carve, and engrave materials with incredible accuracy. For woodworkers, this means intricate designs and seamless joins that enhance the final product. Everyone wants their project to stand out, and CNC routers help achieve that.

Metal fabrication also benefits greatly from CNC technology. These machines efficiently create complex shapes and cuts in various metals. They reduce material waste and speed up production times. However, mastering CNC technology is not always easy. Operators must undergo training to understand programming and machine maintenance properly. Mistakes can happen. Sometimes, the final output may not meet expectations. Constant refinement and learning are part of the process.

In both woodworking and metal fabrication, combining creativity with technology is vital. CNC routers enable better designs and higher productivity. But they won’t do all the work. Human oversight is crucial to ensure quality control. Balancing innovation with skill can lead to remarkable results. Challenges remain, yet the potential rewards are significant.

Investing in a CNC router can be a game-changer for businesses. The return on investment (ROI) associated with these machines is significant. According to a report by the Association for Manufacturing Technology, companies can expect an ROI increase of up to 30% within the first year of operation. This figure is striking, especially considering the versatility of CNC routers in various industries, including woodworking, metalworking, and acrylic fabrication.

The precision and speed of CNC routers reduce labor costs. They automate processes that once required manual labor, which can be expensive. A study from the Society of Manufacturing Engineers highlights that automation can decrease production time by 50%, leading to quicker project turnaround and increased revenue. However, businesses must also consider the initial investment and maintenance costs. While many operators report benefits, some firms find ongoing upkeep challenging.

Understanding cost-effectiveness also means examining potential downsides. Not all projects benefit equally from CNC technology. Smaller projects might not justify the investment. Additionally, companies unprepared for the learning curve may face obstacles. The key is to assess project needs carefully. Analyzing these factors helps businesses make informed decisions.

| Feature | Benefit | Application | Estimated ROI (%) |

|---|---|---|---|

| Precision Cutting | High accuracy in design execution | Signage, furniture making | 30% |

| Versatility | Able to work with various materials | Wood, metals, plastics | 40% |

| Automation | Reduces manual labor and errors | Mass production, repeatability | 50% |

| Cost-Effectiveness | Reduces waste and lowers production costs | Prototyping, small batch production | 35% |

| Speed | Faster production times compared to traditional methods | Custom parts, rapid prototyping | 45% |

CNC router technology is evolving quickly. Innovations are shaping how projects are executed across industries. For instance, a recent industry report indicates that the CNC machining market is expected to grow to $100 billion by 2026. This upward trend highlights the importance of adopting advanced CNC routers.

One area witnessing rapid change is automation. Intelligent routers can now adjust settings on-the-fly. This means less downtime and increased efficiency. However, challenges remain. Not all companies can afford to upgrade their equipment. Moreover, there is a skill gap. Many operators need additional training to use these advanced technologies effectively.

Another trend is the shift toward eco-friendly materials. The rise in demand for sustainable practices has prompted CNC manufacturers to innovate. Reports suggest that 30% of businesses are now prioritizing green materials. Nonetheless, transitioning to these practices isn't straightforward. Cost and availability of these materials may hinder progress. The industry must find ways to balance innovation with practicality.