The manufacturing landscape is rapidly evolving, driven by technological advancements and the integration of smart machinery. Among these innovations, "4 Axis Machines" have emerged as game-changers in enhancing production efficiency. According to a recent report by *MarketsandMarkets*, the CNC machine market, which includes 4 axis machines, is expected to reach $100 billion by 2025, growing at a CAGR of 6.2% from 2020. These machines offer increased flexibility and precision, allowing manufacturers to produce complex parts in a single setup, significantly reducing cycle time and operational costs. Furthermore, in a survey conducted by *IndustryWeek*, 75% of manufacturers reported that implementing advanced manufacturing solutions like 4 Axis Machines has directly improved their productivity and competitiveness in the global market. As we explore the future of manufacturing, it is clear that the adoption of 4 Axis Machines is crucial for companies looking to thrive in an increasingly automated industry.

The Role of 4 Axis Machines in Modern Manufacturing Processes

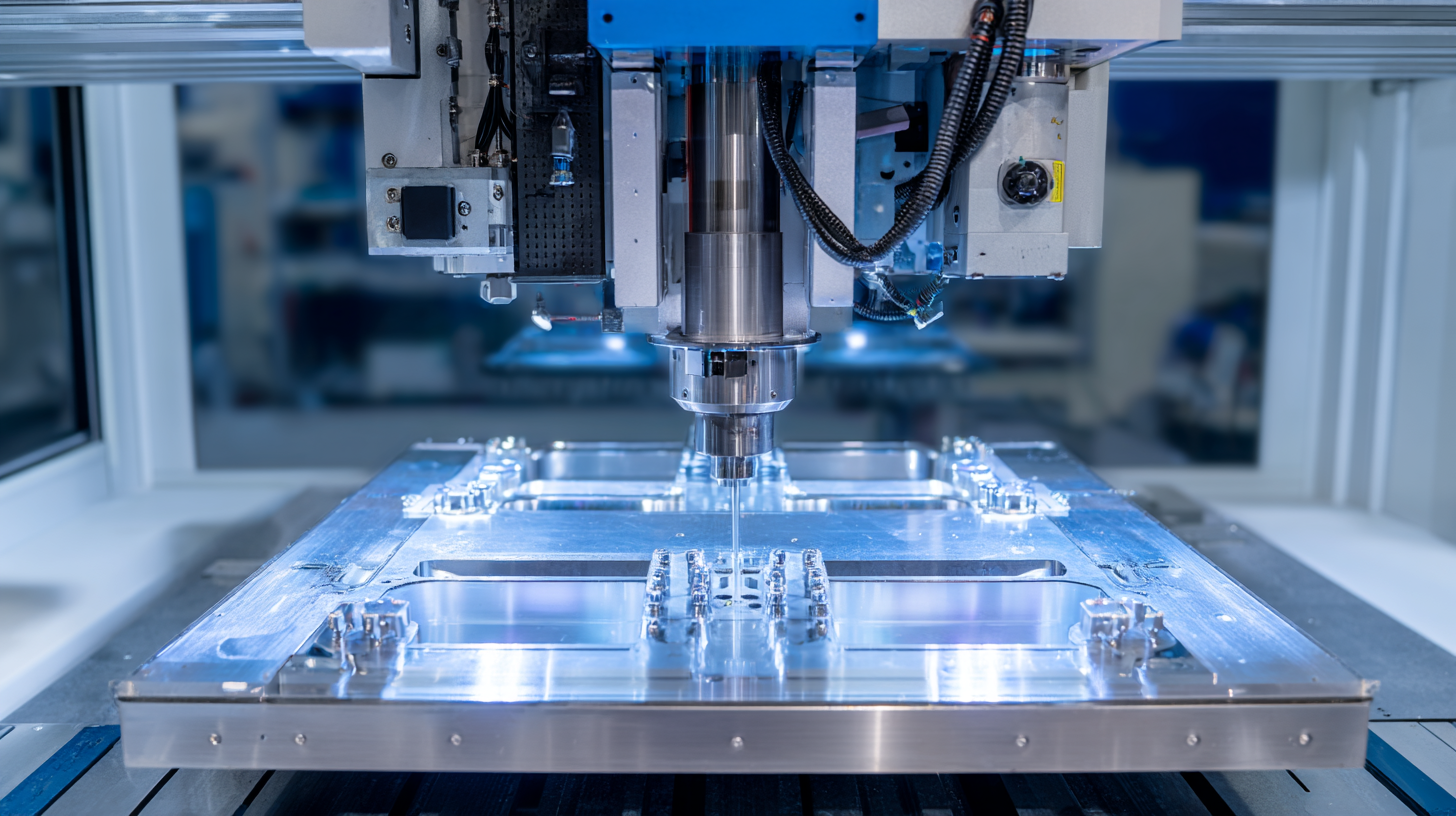

In recent years, the manufacturing sector has witnessed substantial advancements, with 4 axis machines emerging as a critical component in optimizing production efficiency. These machines facilitate complex machining tasks by allowing for simultaneous movement along four different axes. According to a report by Deloitte, manufacturers who have integrated advanced manufacturing technologies, such as 4 axis machining, have reported up to a 20% increase in operational efficiency. This capability not only reduces cycle time but also enhances dimensional accuracy, meeting the tight tolerances demanded by today's competitive market.

Tips: When considering the adoption of 4 axis machines, evaluate your current workflow for stages that could benefit from automation. Transitioning gradually and training your workforce can lead to a smoother implementation and quicker realization of benefits.

Moreover, 4 axis machines enable greater flexibility in manufacturing processes, allowing for the production of intricate designs without the need for multiple setups. A survey by the Manufacturing Institute indicates that companies utilizing advanced machinery can diversify their product offerings by 30% more than those relying on traditional methods. This flexibility is vital in a market that increasingly demands customization and rapid prototyping.

Tips: Prioritize regular maintenance and staff training to maintain the longevity and efficiency of your 4 axis machines. Investing in your equipment and workforce can significantly impact productivity and product quality.

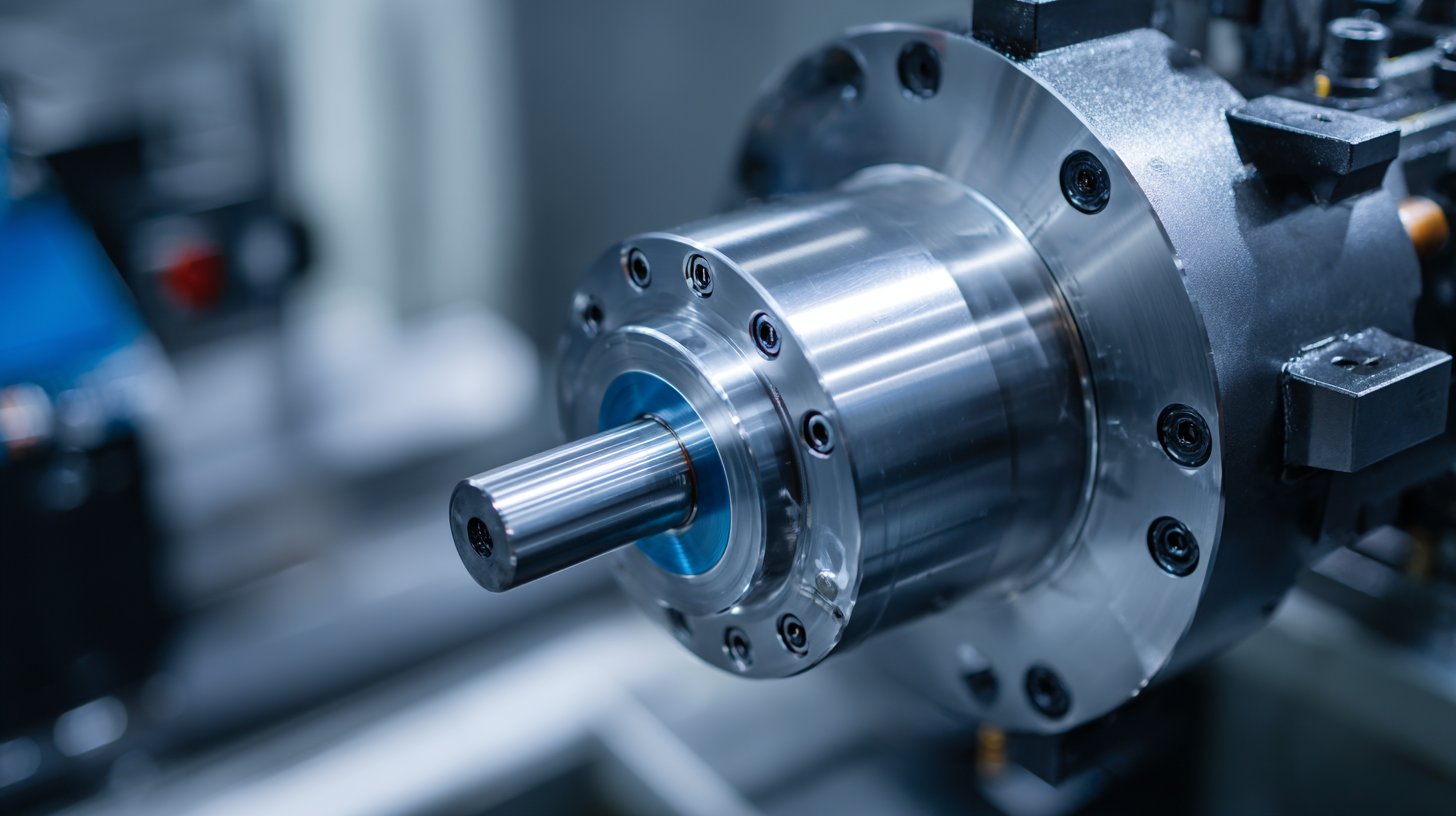

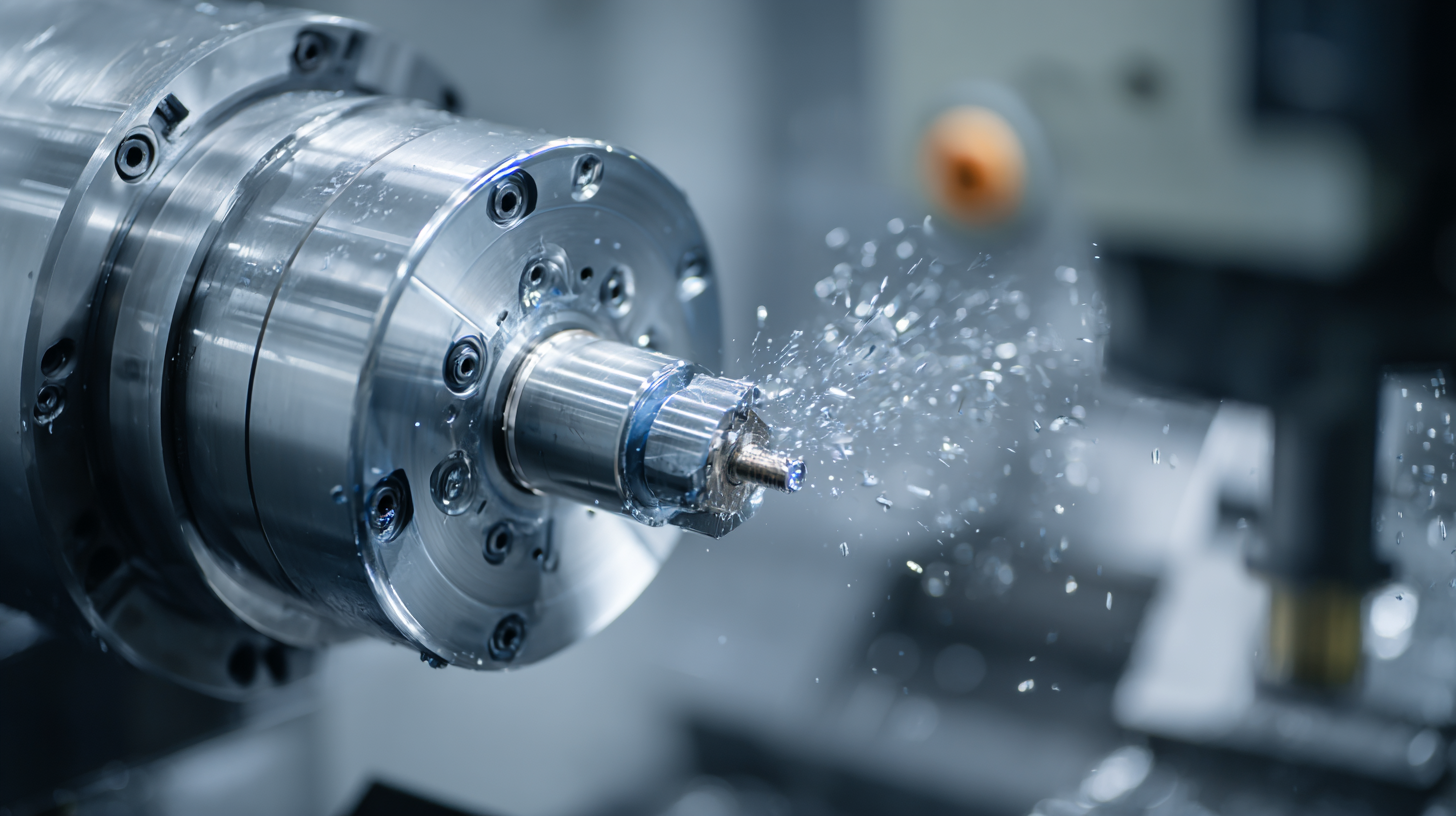

The advent of 4 axis machining centers is significantly enhancing production efficiency and precision in the manufacturing sector. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2026, driven largely by advancements in automation technologies, including 4 axis machines. These machines allow for continuous rotation around one additional axis, enabling manufacturers to produce complex geometries with much less setup time compared to traditional 3 axis machining.

One of the key benefits of 4 axis machines is their ability to perform multiple operations in a single setup, which drastically reduces production time. A study conducted by SME shows that manufacturers utilizing 4 axis technology can achieve up to a 20% increase in overall productivity. Moreover, precision is greatly enhanced; 4 axis machines maintain tighter tolerances, which is crucial for industries such as aerospace and medical device manufacturing where accuracy is paramount. The efficiency gained leads to not only faster turnarounds but also reduced waste, ultimately contributing to lower operational costs and improved bottom lines for manufacturers embracing this technology.

The manufacturing industry is undergoing a significant transformation, particularly with the adoption of

4 axis machinery. According to a recent report by

MarketsandMarkets, the global 4 axis CNC machining market is expected to grow from

$2.3 billion in 2021 to approximately $4.1 billion

by 2026, at a compound annual growth rate (CAGR) of 12.3%.

This surge is driven by the increasing demand for complex geometries and improved production efficiency,

which 4 axis machines are uniquely capable of delivering. As manufacturers seek to streamline their operations

and reduce lead times, the shift towards automation and advanced machinery becomes imperative.

The manufacturing industry is undergoing a significant transformation, particularly with the adoption of

4 axis machinery. According to a recent report by

MarketsandMarkets, the global 4 axis CNC machining market is expected to grow from

$2.3 billion in 2021 to approximately $4.1 billion

by 2026, at a compound annual growth rate (CAGR) of 12.3%.

This surge is driven by the increasing demand for complex geometries and improved production efficiency,

which 4 axis machines are uniquely capable of delivering. As manufacturers seek to streamline their operations

and reduce lead times, the shift towards automation and advanced machinery becomes imperative.

Tips: When considering the integration of 4 axis machinery, manufacturers

should conduct a thorough analysis of their production needs and capabilities. This ensures that the selected

machines are well-aligned with their operational goals. Additionally, investing in employee training can enhance

productivity, allowing teams to maximize the capabilities of these advanced machines.

Another key statistic highlights that more than 70% of manufacturers are planning to

invest in advanced manufacturing technologies, including 4 axis machines, over the next five years as reflected

in a report by Deloitte. This trend illustrates a decisive move towards modernization,

as companies aim to stay competitive in a rapidly evolving market. Embracing this technology can lead to enhanced

flexibility in design and production processes, ultimately resulting in higher product quality and customer satisfaction.

Tips: To stay ahead in this competitive landscape, companies should maintain

an ongoing assessment of technological advancements and continuously adapt their strategies to leverage these

innovations effectively.

The rise of 4 axis machines marks a significant transformation in manufacturing processes compared to traditional techniques. Traditional manufacturing often relies on 3 axis milling and turning methods, which can limit the complexity and precision of machined parts. In contrast, 4 axis machines introduce an additional rotational axis, allowing for more intricate designs and enhanced capabilities. This evolution not only increases the scope of what can be manufactured but also minimizes setup times and maximizes operational efficiency.

When comparing productivity, 4 axis machines generally outperform their traditional counterparts. They enable continuous machining processes without the need for frequent repositioning of the workpiece. This leads to higher throughput and reduced cycle times. Furthermore, by accommodating more complex geometries in a single setup, manufacturers can achieve better accuracy and consistency in their products. The integration of advanced technology in 4 axis machining not only streamlines operations but also opens the door to innovations in product design, ultimately heralding a new era in manufacturing efficiency.

The advent of 4-axis machines is set to transform manufacturing efficiency, especially through their integration into supply chain processes. These advanced machines enable more complex and precise machining operations, leading to enhanced productivity and reduced lead times. As industries increasingly embrace digital innovation policies, the ability to efficiently respond to market demands is becoming paramount. Gartner reports a robust growth in the global supply chain management solutions market, expected to reach $65.8 billion by 2032, underscoring the shift towards automated and digital methodologies that enhance operational effectiveness.

In this evolving landscape, the role of 4-axis technology cannot be overstated. It not only streamlines manufacturing but also plays a crucial role in sustainable development. As companies invest in these innovations, they align their operations with global trends, shifting towards more resilient and sustainable supply chains. This is particularly vital as businesses seek to mitigate risks associated with geopolitical uncertainties and the fast-paced changes in the market. By integrating advanced machining technology, firms are better equipped to navigate future challenges while ensuring a more sustainable operational footprint.