In the world of precision manufacturing, the choice of equipment can significantly influence the outcome of any project. As industry expert John Smith, a renowned CNC technician with over 20 years of experience, aptly put it, "Investing in a heavy duty CNC router is not just about cutting materials; it's about pushing the boundaries of what is possible in design and production." The significance of choosing a heavy duty CNC router lies in its ability to handle complex tasks with precision and durability, making it an invaluable tool for any serious workshop.

Heavy duty CNC routers are engineered to withstand the rigors of demanding applications, providing the strength and reliability necessary for working with a variety of materials, from hardwoods to composites. Their robust construction allows them to achieve high-quality results while maintaining speed and efficiency. This is particularly important for industries that require large-scale production without compromising on accuracy, where every cut counts toward the final product’s quality.

Moreover, investing in a heavy duty CNC router can lead to enhanced creativity and innovation in designs. As projects grow more intricate, having equipment that can meet the challenges head-on becomes essential. Thus, selecting a heavy duty CNC router for your next project not only ensures superior performance but also opens new avenues for potential growth and exploration in the manufacturing landscape.

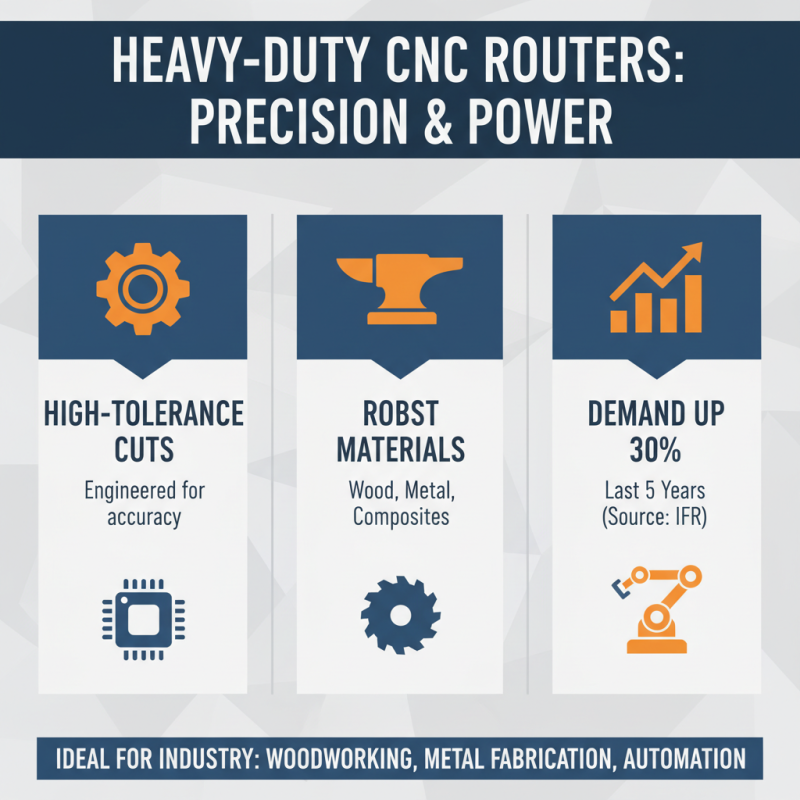

When considering a CNC router for your next project, understanding what constitutes a heavy-duty CNC router is crucial. Heavy-duty CNC routers are engineered for high-tolerance cuts and robust materials, making them ideal for industries ranging from woodworking to metal fabrication. According to a report by the International Federation of Robotics, the demand for high-performance CNC routers has increased by over 30% in the past five years, driven by advancements in automated technology and manufacturing precision.

These machines are built with stronger frames and components designed to withstand extensive wear and tear. Features such as high-torque spindles and advanced motion systems enhance their capability to cut through dense materials like hardwood, plastics, and even metals. Industries report significant reductions in production time and costs due to the efficiency of using heavy-duty CNC routers, facilitating tasks that would typically require multiple machines.

Tips: When selecting a heavy-duty CNC router, consider the following: ensure that the machine has a sufficient weight capacity for your material types; check for enhanced cooling systems to prevent overheating during prolonged use; and look for machines with modular setups that allow for future upgrades. By choosing the right heavy-duty CNC router, you set your project up for long-term success and efficiency.

Heavy duty CNC routers are designed to handle the most demanding machining tasks, offering a range of key features that set them apart from standard models. One of the standout characteristics is their robust construction, which typically includes a reinforced frame and high-quality materials. This not only ensures stability during operation but also reduces vibrations that can affect precision. The increased weight capacity allows these routers to support larger workpieces, making them ideal for projects that require extensive machining on materials like hardwood, aluminum, and composite materials.

Another critical feature of heavy duty CNC routers is their powerful spindle motors, which provide consistent power and speed even under heavy loads. This capability enables faster cutting speeds and improved efficiency, essential for high-volume production environments. Additionally, these machines often incorporate advanced cooling systems to prevent overheating during prolonged use. The enhanced software controls available with heavy duty routers also allow for more intricate designs, enabling users to execute complex patterns with greater accuracy and repeatability, ultimately leading to superior finished products.

When considering a heavy-duty CNC router for your next project, there are several distinct advantages that can significantly enhance your production quality and efficiency. Heavy-duty CNC routers are designed to tackle demanding tasks involving robust materials such as hardwoods, metals, and plastics. According to a report by TechNavio, the global CNC machining market is expected to grow by over 6% from 2020 to 2024, highlighting the increasing reliance on high-performance machinery in various industries. Their durability allows for continuous use, reducing downtime and maintenance costs, ultimately leading to increased productivity.

One key advantage of heavy-duty CNC routers is their ability to process larger workpieces with precision. These machines feature powerful motors and advanced spindle technology, enabling them to maintain speed and accuracy even under significant load. A study published in the Journal of Manufacturing Science and Engineering indicates that the accuracy of CNC machines can be improved by up to 30% when using heavy-duty systems, which is critical for applications requiring tight tolerances.

**Tips:** When investing in a heavy-duty CNC router, consider the key specifications such as spindle power, bed size, and material compatibility to ensure it meets your specific project needs. Additionally, implementing regular maintenance schedules can prolong the life of your machinery and sustain optimal performance levels. Furthermore, training your team on best practices in operating these machines not only enhances safety but also maximizes operational efficiency.

Heavy duty CNC routers are essential tools in various industries due to their ability to handle a wide range of materials with precision and efficiency. In the woodworking industry, these routers are particularly valuable for creating intricate designs in hardwood, plywood, and other materials. They enable manufacturers to cut, carve, and engrave with high accuracy, making them ideal for producing furniture, cabinetry, and custom fixtures. The robustness of heavy duty CNC routers ensures they can operate continuously in high-demand environments, ultimately increasing production rates and reducing labor costs.

In the metalworking sector, heavy duty CNC routers play a significant role in shaping and fabricating metal components. They provide the capability to work with tough materials like aluminum and steel, allowing for the creation of complex parts used in automotive, aerospace, and machinery applications. These routers are equipped with powerful spindles and advanced tooling systems that enhance their cutting capabilities, making them indispensable for prototyping and production runs. Additionally, the versatility of CNC technology allows for seamless transitions between different projects and material types, further broadening their application across diverse industries.

When selecting a heavy-duty CNC router for your project, several key factors should be taken into account to ensure you make the best choice for your specific needs. First and foremost, consider the material you'll be working with. Heavy-duty CNC routers are capable of handling a variety of materials such as hardwoods, composites, and metals, so it’s crucial to choose a machine that can accommodate the thickness and density of the materials used in your projects. Additionally, examine the cutting speed and power of the router. Higher horsepower and RPMs will allow for faster processing times and more intricate designs.

Another important aspect to evaluate is the size and workspace of the CNC router. Depending on your project requirements, you may need a larger work area to accommodate bigger pieces or intricate designs. Assessing the machine’s bed size is vital, as this determines the maximum dimensions of the materials you can work with. Furthermore, consider the machine’s software compatibility and ease of use. A user-friendly interface and robust software can significantly enhance productivity and reduce the learning curve, making it easier to transition into more complex projects. By taking these factors into consideration, you can select a heavy-duty CNC router that aligns perfectly with your project’s demands.

| Feature | Description | Benefits |

|---|---|---|

| Rigid Frame | Constructed from high-quality welded steel for stability. | Enhances accuracy and reduces vibration during operation. |

| High Precision Spindles | Equipped with superior spindles for smoother cutting. | Achieves fine details and complex designs in materials. |

| Larger Work Area | Generous workspace allowing larger projects. | Increases project versatility and efficiency. |

| Sturdy Tool Holders | Robust holders ensuring tools are securely in place. | Reduces tool wear and enhances tool performance. |

| Advanced Software | Integration with modern CAD/CAM software. | Streamlines design and manufacturing processes. |