In the world of door installation, precision and efficiency are paramount. Hinge Hole Drilling Machines have revolutionized the way carpenters and contractors approach this task, ensuring that each installation is executed flawlessly. According to John Carter, a leading expert in woodworking technology, "Investing in high-quality hinge hole drilling machines is essential for achieving that perfect fit and finish that every installation demands."

The effectiveness of these machines lies in their ability to create perfectly aligned hinge holes, which directly impacts the functionality and aesthetics of the door. As the industry evolves, so do the technologies surrounding hinge hole drilling, allowing professionals to reduce human error and enhance overall productivity. This guide delves into the features, benefits, and best practices associated with hinge hole drilling machines, equipping you with the knowledge needed to elevate your door installation projects. Whether you're a seasoned contractor or a DIY enthusiast, understanding the nuances of these machines can make all the difference in your woodworking endeavors.

Hinge hole drilling machines play a crucial role in the installation of doors, ensuring precision and efficiency. These specialized tools are designed to create perfect hinge recesses, which are vital for the seamless operation of doors. The importance of using a hinge hole drilling machine lies in its ability to standardize the hinge placement, reducing the risk of misalignment that could lead to functional issues or damage over time.

When selecting a hinge hole drilling machine, consider the following tips: First, ensure that the machine offers adjustable settings to accommodate different hinge sizes and types. This versatility allows for various door installations without compromising quality. Secondly, always prioritize safety features, such as emergency stops and protective guards, to safeguard against accidents during operation. Lastly, invest time in learning proper techniques for using the machine; practice on scrap wood can help refine your skills for the actual installation.

By understanding the importance of hinge hole drilling machines and adhering to best practices, you can achieve professional results in your door installation projects. The right tools combined with a solid technique pave the way for durable and functional doors that enhance both aesthetics and practicality in your space.

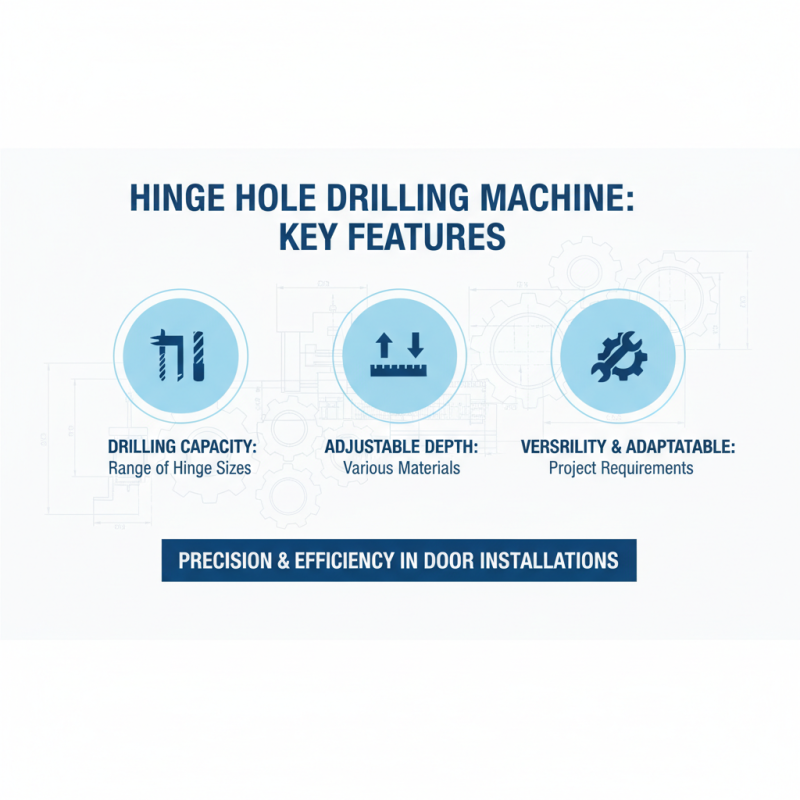

When selecting a hinge hole drilling machine, several key features are essential for ensuring precision and efficiency in door installations. One of the primary aspects to consider is the machine's drilling capacity, which should ideally accommodate a range of hinge sizes and types. Reports indicate that machines with adjustable drilling depth can enhance versatility, allowing operators to work with different materials and thicknesses, thus making the setup more adaptable to various project requirements.

Another vital feature is the presence of a reliable guide or alignment system. Industry studies reveal that machines equipped with laser guides or built-in templates significantly increase the accuracy of drill placements. This not only improves the quality of the installation but also reduces material waste by minimizing the chances of misdrilling. Furthermore, the ease of use is paramount; machines that offer user-friendly controls and settings can lead to higher productivity rates and less downtime, making them a smart investment for professionals.

Lastly, durability and build quality should not be overlooked. According to recent market analyses, machines constructed from high-grade materials tend to have longer lifespans and require less maintenance, directly impacting overall operational costs. Investing in a reliable hinge hole drilling machine can enhance workflow efficiency and ensure that installations meet the highest standards of craftsmanship.

Using a hinge hole drilling machine may seem daunting at first, but following a

structured step-by-step guide can make the process smooth and effective. First, ensure you have all necessary tools ready,

including the drilling machine, an appropriate drill bit for the hinge size, and a measuring tape. Start by marking the exact location

where the hinge will be installed on the door edge. Measurement accuracy is crucial, so

double-check that the marks align perfectly with the corresponding marks on the door frame.

Once your markings are in place, securely fasten the door to prevent movement during drilling. Position the hinge hole drilling machine

over the marked spot and carefully adjust the depth setting according to the thickness of the door. Start the drill at a

low speed to make a clean entry into the wood, gradually increasing speed as needed. As you drill, maintain a steady hand to ensure

a straight hole. After creating the hinge holes, clean up any wood dust and check that the holes fit the hinge perfectly

before installation. This attention to detail will lead to a professional-looking hinge installation.

When it comes to door installation, achieving precise hinge placement is critical for both functionality and aesthetics. Research shows that improperly installed hinges can lead to misalignment and premature wear, which may necessitate costly repairs. According to industry reports, up to 30% of door-related issues stem from poor hinge positioning, underscoring the importance of utilizing the right tools and techniques during the installation process. A quality hinge hole drilling machine is essential for ensuring accuracy in hinge placement and enhancing the overall durability of the door structure.

To achieve accurate door hinge placement, one must begin with meticulous measurements. The standard distance for hinge placement, typically 7 inches from the top of the door to the centerline of the top hinge, and 11 inches from the bottom, should be strictly adhered to. Furthermore, using a reliable hinge hole drilling machine equipped with depth control and adjustable settings can help avoid common pitfalls, such as drilling too deep or at incorrect angles. Studies indicate that drill errors can lead to up to 15% more time spent on adjustments, making it essential for professionals and DIY enthusiasts alike to invest in tools that enhance precision and reduce the risk of costly mistakes.

When it comes to drilling hinge holes for door installation, precision is paramount. A common mistake that many professionals make is failing to properly measure and mark the locations for hinge placement. According to a report by the National Association of Home Builders, improper alignment can lead to significant issues, such as doors that do not close properly or hinges that wear out more quickly than expected. Taking the time to accurately measure and mark the placement of hinges is crucial to ensuring that the door functions as intended.

Another frequent error is using the wrong drill bit for the job. Many installers underestimate the importance of selecting the appropriate size and type of drill bit, which can result in oversized or undersized hinge holes. Research from the Woodwork Institute suggests that using a bit that matches the hinge’s specifications ensures a snug fit, reducing the likelihood of hinge failure over time. Additionally, ensuring that the drill is at the correct angle and depth will mitigate the risk of cracking the door frame, which can further complicate installation. By addressing these common mistakes, installers can achieve flawless door installations that stand the test of time.

| Mistake | Description | Prevention Tip |

|---|---|---|

| Incorrect Measurements | Failure to measure the hinge placement accurately can lead to misalignment. | Always double-check measurements before drilling. |

| Using Wrong Drill Bit Size | Using a drill bit that is too large or too small can damage the hinge or wood. | Refer to hinge specifications for the correct drill bit size. |

| Drilling at Incorrect Angles | Drilling at the wrong angle can lead to a poor fit and functional issues. | Use a protractor or drilling guide to ensure the correct angle. |

| Neglecting Material Type | Drill bits may behave differently based on the material of the door. | Select drill bits designed for the specific material being worked on. |

| Forgetting to Secure the Door | A loose door can shift while drilling, causing inaccuracies. | Ensure the door is properly secured before drilling. |