In today's highly competitive industrial landscape, the pursuit of maximum efficiency and performance is critical for sustaining growth and profitability. A recent report by McKinsey & Company highlights that organizations implementing strategies for optimizing machines can achieve up to a 20% increase in productivity. This statistic underscores the importance of proactive measures in equipment management and the optimization of operational processes.

Optimizing machines not only enhances productivity but also plays a pivotal role in reducing operational costs. According to a study by the International Energy Agency (IEA), optimally maintained machinery can lead to energy savings of 10-30%, depending on the industry and application. As industries increasingly focus on sustainability and energy efficiency, seeking ways to enhance the performance of machinery becomes essential.

Furthermore, the integration of advanced technologies such as predictive maintenance and IoT solutions has revolutionized the optimizing machines process, leading to real-time analytics and decision-making that can significantly minimize downtime. By leveraging these technologies, organizations can not only maximize their equipment's lifespan but also maintain a competitive edge in an ever-evolving market. Thus, the focus on optimizing machines is not merely an operational necessity but a strategic imperative for future success.

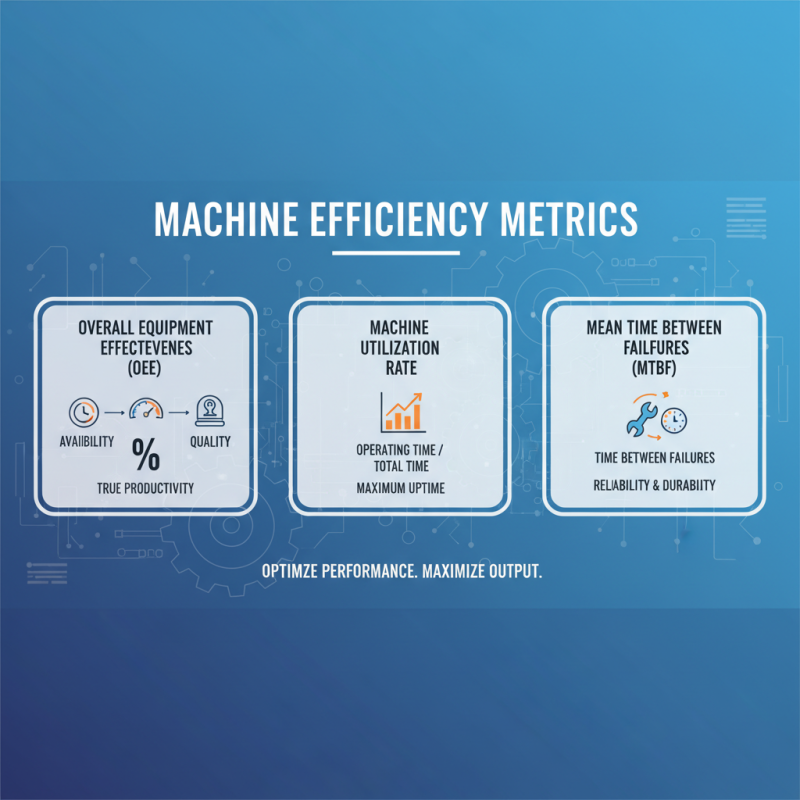

Understanding machine efficiency metrics is crucial for optimizing performance and attaining maximum output in any industrial setting. Several key performance indicators (KPIs) can provide valuable insights into how machines are operating. Metrics such as Overall Equipment Effectiveness (OEE), machine utilization rates, and mean time between failures (MTBF) offer a comprehensive view of performance. OEE, for instance, combines the measures of availability, performance, and quality to reveal the true productivity of a machine. It allows operators to identify inefficiencies and prioritize areas for improvement.

Additionally, tracking energy consumption alongside production output can surface additional opportunities for optimization. Metrics like energy efficiency ratio (EER) can help assess how much energy is being used relative to the amount of output produced. By analyzing these metrics regularly, businesses can make informed decisions about maintenance schedules, potential upgrades, and process adjustments, ultimately enhancing the longevity and effectiveness of their machinery. Applying these metrics strategically not only drives performance but also contributes to sustainability efforts by minimizing waste and energy usage.

Assessing the current performance of machines is crucial for optimizing efficiency and output. One key technique is conducting a thorough performance audit. This entails measuring metrics such as speed, output levels, and energy consumption over a defined period. By gathering this data, operators can identify bottlenecks and areas that require enhancement. For instance, analyzing downtime instances can reveal patterns that indicate whether the root cause lies in machine malfunctions or suboptimal scheduling.

Tips: Regularly monitor machine metrics with performance dashboards that visualize data trends. This not only helps in identifying inefficiencies but also allows for prompt intervention before minor issues escalate.

Another effective method is implementing predictive maintenance using real-time data analytics. By leveraging sensors and IoT technology, operators can monitor machine health continuously. This approach enables the anticipation of failures before they occur, thereby minimizing unplanned downtime and optimizing productivity.

Tips: Train your workforce to comprehend the data output, focusing on actionable insights from analytics. When employees are equipped with the knowledge of machine performance statistics, they can contribute to timely decision-making, enhancing overall operational efficiency.

| Machine Type | Current Speed (units/hour) | Output (units/day) | Efficiency (%) | Recommended Improvements |

|---|---|---|---|---|

| CNC Lathe | 120 | 960 | 85 | Upgrade tooling, implement predictive maintenance |

| Injection Molding Machine | 200 | 1600 | 90 | Optimize cycle time, enhance material flow |

| 3D Printer | 50 | 400 | 75 | Improve software algorithms, calibrate regularly |

| Laser Cutter | 70 | 560 | 80 | Adjust laser focus, maintain lens cleanliness |

| Band Saw | 90 | 720 | 78 | Regular blade changes, enhance blade lubrication |

Advanced maintenance strategies play a crucial role in reducing downtime and maximizing the utilization of machines in various industries. According to a report by McKinsey, companies that adopt rigorous maintenance practices can reduce machine downtime by up to 30%. Implementing predictive maintenance techniques, using data analytics and IoT sensors, allows businesses to anticipate equipment failures before they occur, thereby optimizing scheduling and resource allocation. This approach not only enhances the lifespan of machinery but also provides a significant return on investment through increased operational efficiency.

Moreover, traditional reactive maintenance can often lead to inflated costs and unexpected production halts. The same McKinsey report highlights that industries utilizing advanced maintenance strategies can achieve up to 25% lower overall maintenance costs. By investing in regular training for maintenance teams and integrating advanced monitoring systems, companies can ensure that machinery operates at peak performance levels. This not only sustains productivity but also fosters a culture of continuous improvement, where operational bottlenecks are regularly identified and addressed proactively. In a competitive marketplace, these strategies are essential for businesses striving to maintain a leading edge.

The integration of automation technologies has emerged as a pivotal strategy for optimizing machines and enhancing operational efficiencies across various industries. According to a report by McKinsey & Company, companies that integrate automation into their processes can achieve productivity gains of 20% to 30%. By leveraging data-driven optimization tools, organizations can systematically analyze machine performance and identify bottlenecks, leading to significant reductions in downtime and operational costs.

Data analytics plays a crucial role in this optimization process. By employing advanced algorithms and machine learning models, businesses can derive actionable insights from vast datasets, allowing them to fine-tune machine operations in real-time. A survey by Deloitte revealed that 61% of organizations utilizing machine learning for process improvement reported improved operational efficiency. Furthermore, predictive maintenance powered by data analytics can proactively address maintenance issues, thereby extending machine lifespan and avoiding costly repairs.

Implementing these automation technologies not only enhances machine performance but also fosters a culture of continuous improvement. As organizations embrace data-driven decision-making, they position themselves to adapt swiftly to market changes and complex production demands. The rise of smart factories, as reported by the World Economic Forum, indicates that optimized automation strategies are no longer optional but essential for competitiveness in today's fast-paced manufacturing landscape.

Investing in training and skill development is essential for enhancing operator effectiveness, which directly impacts the efficiency and performance of machines. Operators who are well-trained understand the nuances of the equipment they work with, allowing them to identify potential issues before they escalate into significant problems. This proactive approach not only minimizes downtime but also maximizes productivity, as trained operators can operate machinery at optimal levels while adhering to safety protocols.

Moreover, continuous development programs foster a culture of learning and adaptation within the workforce. Through workshops, hands-on training, and simulations, operators can keep up with advancements in technology and industry best practices. This knowledge equips them to leverage machine capabilities fully and creatively to solve operational challenges. As operators gain confidence in their skills, they contribute more effectively to team goals, leading to better overall results for the organization. Thus, prioritizing training and skill development not only enhances individual performance but also drives collective success.