In the rapidly evolving landscape of modern manufacturing, the introduction of 5 Axis Machines has revolutionized production capabilities, offering unmatched precision and efficiency. According to a recent report by Market Research Future, the global 5-axis machining market is projected to grow at a CAGR of over 6% from 2022 to 2027, driven by the increasing demand for complex and high-precision components across various industries, including aerospace and automotive.

These advanced machining centers, which allow movement along five different axes simultaneously, not only enhance machining accuracy but also significantly reduce production times and costs. As manufacturers strive to improve their competitive edge, the adoption of 5 Axis Machines is proving to be a pivotal factor in achieving operational excellence and meeting the diverse needs of customers in a fast-paced market.

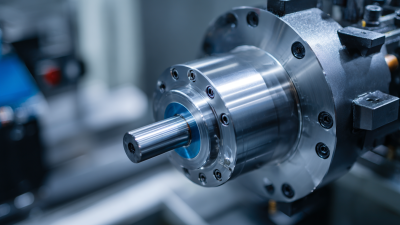

5-axis machining is a cutting-edge manufacturing technique that enhances the capabilities of traditional milling processes by allowing tools to move along five different axes simultaneously. This advanced method provides unparalleled precision when creating complex geometries and intricate designs, making it indispensable in industries such as aerospace, automotive, and medical device manufacturing. By utilizing a multi-faceted approach, manufacturers can reduce the number of workpieces and setups required, significantly decreasing production time and costs while improving overall efficiency.

The advantages of 5-axis machining extend beyond just speed and cost-effectiveness. This technology facilitates the creation of high-quality surfaces and intricate shapes that would be challenging or impossible to achieve with 3-axis machines. Additionally, it allows for better tool access, reducing the risk of tool interference and enhancing the cutting process. As a result, manufacturers can deliver products that meet stringent specifications and tighter tolerances, ultimately leading to higher customer satisfaction and increased competitiveness in the market.

The adoption of 5-axis machining technology is transforming various industries by enhancing precision and efficiency in manufacturing processes. As reported by market studies, the global multi-axis machining center market is projected to grow from USD 79.4 billion in 2024 to USD 134.9 billion by 2033. This significant increase reflects the high demand for advanced machining capabilities to accommodate the production of complex parts that are becoming standard in sectors such as aerospace, automotive, and medical device manufacturing.

In North Penn, for instance, precision CNC turning has emerged as a key driver of manufacturing innovation, resulting in increased operational efficiency and job creation. Companies utilizing CNC technology are witnessing higher throughput while simultaneously maintaining stringent quality standards. With the right tools and technology, manufacturers can enhance their output and respond more agilely to market demands.

Tips: To leverage the benefits of 5-axis machining, manufacturers should consider investing in training for their workforce to maximize the technology's potential. Additionally, integrating advanced CAD software can streamline design processes and further enhance production efficiency, positioning companies for success in an increasingly competitive landscape.

The comparative analysis between 5-axis and traditional machining methods reveals significant differences in production costs and efficiency. 5-axis machining, characterized by its ability to simultaneously move a tool across five different axes, allows for the creation of complex geometries that are increasingly demanded in industries like aerospace and automotive. This capability not only enhances precision but also reduces cycle times, leading to lower labor and operational costs. In contrast, traditional machining methods often require multiple setups for similar tasks, extending lead times and increasing potential for human error.

The evolving landscape of digital manufacturing technologies, particularly in the context of 5-axis CNC machines, has revolutionized the production process. By optimizing tool paths and minimizing setup times, companies can significantly cut down on material waste and improve overall sustainability. This shift toward more advanced machining technologies not only supports the manufacturing of high-performance components but also contributes to economic competitiveness in an increasingly global market. The convergence of cost efficiency and precision engineering positions 5-axis machining as a pivotal player in modern manufacturing practices.

In the realm of modern manufacturing, 5-axis machines have transformed the landscape, allowing for unprecedented precision and efficiency. Enterprises that have successfully implemented these advanced machines witness remarkable improvements in their production capabilities. One notable example can be found in the aerospace sector, where a leading manufacturer adopted 5-axis machining to create complex components with tighter tolerances. This not only reduced waste but also accelerated their production timelines, enabling them to meet rising industry demands.

Tips for successful implementation of 5-axis machines include investing in thorough training for staff to ensure they can maximize the machines' capabilities. Regular maintenance schedules are crucial; keeping the machines in optimal condition helps prevent costly downtimes. Additionally, integrating intelligent robotics can further enhance productivity in manufacturing environments, akin to the advancements seen in the field of geriatric rehabilitation, where robotics are making significant strides.

By focusing on these practical steps, modern enterprises can harness the full potential of 5-axis technology, driving innovation and efficiency in their manufacturing processes.

| Implementation Case | Industry | Objective | Achieved Efficiency (% Improvement) | Reduction in Waste (% Savings) | Overall Impact |

|---|---|---|---|---|---|

| Case Study A | Aerospace | Streamline parts production | 25% | 15% | Enhanced competitiveness |

| Case Study B | Automotive | Increase precision in components | 30% | 20% | Boosted production capacity |

| Case Study C | Medical Devices | Reduce lead time | 40% | 10% | Improved market response |

| Case Study D | Energy | Enhance part reliability | 20% | 5% | Increased operational effectiveness |

| Case Study E | Robotics | Improve design precision | 35% | 25% | Strengthened innovation |

The integration of automation and artificial intelligence (AI) in 5-axis machining techniques is transforming modern manufacturing landscapes. As the demand for high precision and efficiency increases, manufacturers are recognizing the potential of advanced digital technologies. For instance, the Chinese CNC machine tool market reached an impressive scale of 409 billion yuan in 2023, with an annual compound growth rate of 5.75% from 2019 to 2023. This growth trend highlights the escalating necessity for automated solutions that efficiently handle complex machining tasks.

Moreover, with the increasing capabilities of AI, various models have been tested for their performance in parts manufacturing. Adam Karvonen's evaluations reveal that while some AI systems exhibit remarkable potential, others struggle to match the expertise of seasoned machinists. This observation underscores the challenges faced in automating fundamental machining tasks, reinforcing the notion that human skill remains vital in precision manufacturing despite advancements in technology. As the industry progresses, continuous research and development in AI and robotics will be crucial to fully leverage the capabilities of 5-axis machines and drive productivity and precision to unprecedented levels.