As we approach 2025, the urgency for industries to enhance operational efficiency has never been greater. One of the pivotal elements shaping this goal is the practice of optimizing machines. In an era marked by rapid technological advancements and escalating production demands, organizations are compelled to find innovative ways to leverage their machinery for maximum output while minimizing resource consumption. This endeavor is not merely about maintaining competitiveness; it is essential for sustainable development and profitability.

The strategies for optimizing machines encompass a wide range of methodologies, from integrating artificial intelligence and machine learning to adopting predictive maintenance practices. By harnessing data analytics, companies can gain valuable insights into machine performance, enabling them to identify bottlenecks and inefficiencies that may hinder productivity. Furthermore, the growing emphasis on automation and smart technologies facilitates the creation of interconnected systems, where machines can communicate with one another to streamline operations.

As we delve into the top strategies for optimizing machines in 2025, it is crucial to recognize that this transformation demands not just technological upgrades, but also a cultural shift within organizations. Empowering teams with the knowledge and tools necessary for machine optimization is vital for fostering a proactive approach toward efficiency. In this exploration, we will uncover various tactics that can be employed to ensure that machinery is not only operational but is functioning at the peak of its capabilities.

In 2025, optimizing machines for maximum efficiency will rely heavily on advanced technologies and innovative practices. One of the foremost strategies involves the integration of artificial intelligence and machine learning. These technologies can analyze operational data in real-time, enabling machines to adapt and optimize their performance based on varying conditions. By leveraging predictive analytics, organizations can preemptively address potential failures and inefficiencies, thus maintaining peak operational capabilities and minimizing downtime.

Another critical approach is the implementation of the Internet of Things (IoT) for enhanced connectivity and data collection. By equipping machines with IoT sensors, companies gain valuable insights into the performance metrics and energy consumption patterns of their equipment. This data not only helps in optimizing machinery settings for better performance but also facilitates more effective resource allocation. As machines communicate with each other and with central systems, they can operate more cohesively, ensuring that all components work in harmony towards achieving operational goals while reducing wastage and inefficiencies.

In 2025, the integration of artificial intelligence (AI) into machine optimization is set to redefine operational efficiency across industries. According to a report by McKinsey, organizations that leverage AI could boost productivity by up to 40% by automating routine processes and providing real-time insights into machine performance. By utilizing machine learning algorithms, companies can analyze vast amounts of data from their equipment, predicting maintenance needs and optimizing operation schedules with unprecedented accuracy. This proactive approach minimizes downtime and extends the lifespan of machinery, ultimately leading to significant cost savings.

Furthermore, a study by PwC highlights that AI-driven optimization will enable machines to adapt to shifting operational conditions autonomously. In manufacturing settings, for instance, AI can dynamically adjust parameters based on real-time data, maximizing production efficiency while reducing waste. The ability of AI to learn from previous outcomes and continuously improve its algorithms is a game-changer, setting the stage for machines that not only operate efficiently but also evolve in their performance levels. As industries prepare for this AI-augmented future, the focus will shift towards building resilient systems that can thrive in an increasingly complex and competitive landscape.

In 2025, the integration of Internet of Things (IoT) technologies will play a pivotal role in optimizing machine performance and efficiency across various industries. According to a report by McKinsey & Company, IoT could potentially generate up to $11 trillion a year in economic value by 2025, primarily through increased productivity and efficiency in manufacturing processes. By equipping machines with IoT sensors, manufacturers will be able to collect real-time data on performance metrics, allowing for immediate identification of operational bottlenecks and maintenance needs.

The use of predictive analytics powered by IoT data maximizes machines' uptime and efficiency. A study conducted by Deloitte revealed that implementing IoT solutions can lead to a 20-30% reduction in equipment downtime. This is achieved through constant monitoring of machine conditions, enabling proactive maintenance rather than reactive repairs. As data from these IoT devices are analyzed, companies can gain insights that drive continuous improvements in performance metrics, transforming their operational strategies and leading to substantial cost savings over time. Embracing IoT technologies is not just a trend but an essential step for industries aiming to thrive in the competitive landscape of 2025.

As industries gear up for 2025, integrating predictive maintenance techniques is emerging as a key strategy to enhance efficiency and reduce operational costs. Predictive maintenance utilizes data analytics and IoT technologies to monitor the condition of machinery in real-time, allowing for timely interventions before potential failures occur. By analyzing patterns and performance metrics, organizations can forecast when maintenance should take place, striking a balance between routine maintenance schedules and reactive repairs, thereby minimizing unnecessary downtime.

The financial benefits of adopting predictive maintenance are substantial. Reduced unplanned downtime means that machines are kept running longer and more efficiently, leading to increased productivity. Furthermore, by addressing maintenance needs before a breakdown happens, companies can avoid the expensive costs associated with emergency repairs and lost production time. This proactive approach not only extends the lifespan of equipment but also promotes a culture of continuous improvement within organizations, fostering a more agile and resilient operational model that can adapt to the fast-paced demands of modern markets.

| Strategy | Description | Expected Benefits | Implementation Timeline | Cost Savings Estimate |

|---|---|---|---|---|

| Predictive Maintenance | Utilizing IoT sensors and machine learning to predict failures before they occur. | Reduced downtime, extended equipment life, increased productivity. | 6-12 months | 15-30% cost savings |

| Energy Optimization | Implementing smart energy management systems to monitor and reduce energy usage. | Lower energy costs, reduced carbon footprint, enhanced sustainability. | 3-6 months | 10-20% savings on energy costs |

| Process Automation | Automating repetitive tasks using robotic process automation (RPA). | Increased efficiency, reduced error rates, faster production times. | 6-12 months | 20-35% operational cost reduction |

| Data Analytics | Leveraging big data analytics to improve decision-making processes. | Improved insights, faster responses to market changes, reduced waste. | Ongoing | Variable, up to 25% efficiency gains |

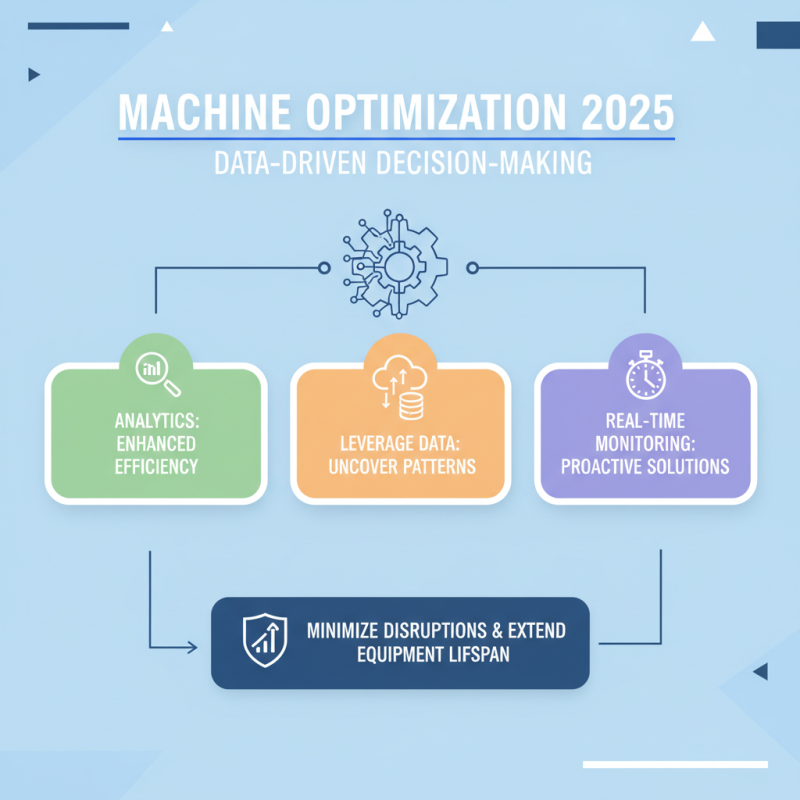

In 2025, the landscape of machine optimization will heavily rely on data-driven decision-making, where analytics play a crucial role in enhancing operational efficiency. By leveraging vast amounts of data generated from various sources, organizations can identify patterns and trends that were previously obscured. Utilizing advanced analytics platforms, companies can monitor machine performance in real time, enabling them to preemptively address issues before they escalate into significant downtime or failure. This proactive approach not only minimizes disruptions but also extends the lifespan of the equipment.

Furthermore, employing predictive analytics allows businesses to understand and anticipate their machinery's needs. By analyzing historical data and operational metrics, organizations can implement tailored maintenance schedules, ensuring that machines are serviced precisely when necessary. This shift towards a more intelligent maintenance strategy helps in avoiding unnecessary costs associated with over-maintenance or emergency repairs. Ultimately, integrating data analytics into the optimization strategy provides a clear competitive edge, allowing companies to maximize their efficiency through informed decision-making.

In 2025, optimizing machines will be crucial for achieving maximum efficiency across various industries. The integration of artificial intelligence (AI) is set to play a vital role in enhancing machine performance, enabling real-time adjustments and smarter operational strategies. Additionally, leveraging Internet of Things (IoT) technologies will facilitate the collection of detailed performance metrics, allowing for more informed decision-making.

Predictive maintenance will further reduce downtime and operational costs by enabling proactive interventions before failures occur. Emphasizing data-driven decision-making through advanced analytics will empower organizations to identify inefficiencies and implement targeted improvements. Lastly, focusing on sustainability practices in machine operations not only boosts efficiency but also promotes long-term viability, aligning with global trends toward environmentally responsible manufacturing. Overall, the strategies outlined will significantly contribute to the effective optimizing of machines for enhanced productivity and operational excellence.