Choosing the right Cabinet Drilling Machines can be a daunting task. Many factors influence your decision. You may feel overwhelmed by the options available.

These machines are essential for producing precise and efficient results. Understanding their features is crucial. You should consider the drilling capacity, accuracy, and build quality. Each factor affects your projects.

However, it's easy to overlook certain aspects. You might focus too much on price or brand reputation. Sometimes, the best machine isn't the most expensive. Reflecting on your specific needs will guide you better. Choosing wisely can enhance your woodworking experience.

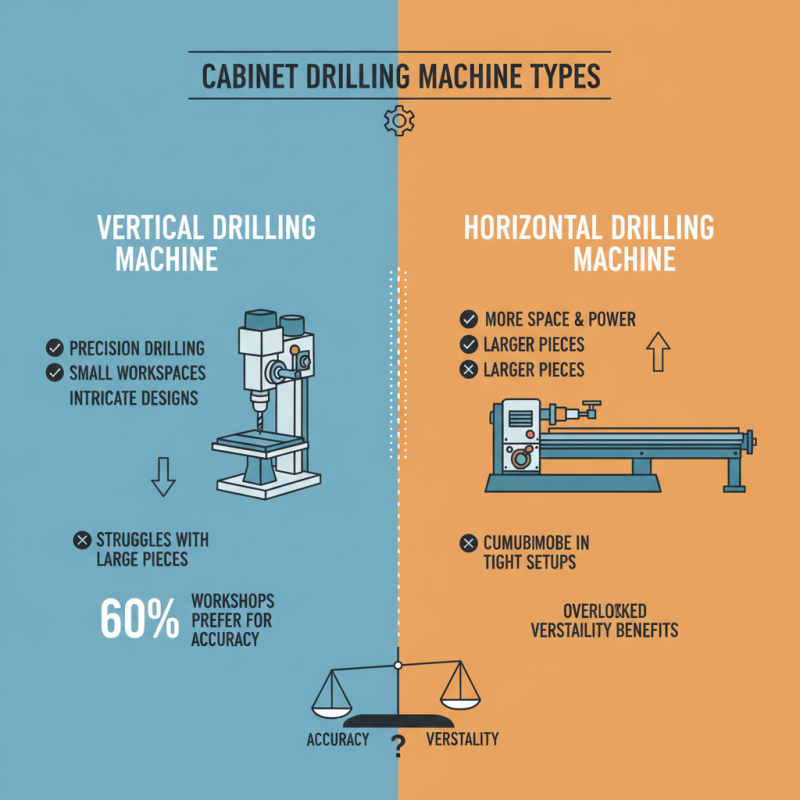

When selecting a cabinet drilling machine, understanding the various types is crucial. Generally, machines fall into categories like vertical and horizontal drilling. Vertical machines are often used for precise drilling in smaller workspaces. They can handle intricate designs, although they may struggle with larger pieces. Horizontal machines, conversely, offer more space and power but can be cumbersome in tight setups. Industry data indicates that about 60% of workshops prefer vertical machines for their accuracy, yet they often overlook the benefits of versatility in horizontal models.

Drilling machines also vary in functionality. Some can perform multiple tasks, including doweling and pocket hole work. Research shows that 70% of users value multifunctional capabilities. However, with added features, complexity can rise. Many users report frustration with the learning curve. These machines can overwhelm beginners. It's important to balance features with ease of use. A too-complex machine can lead to operational errors and wasted materials, highlighting the need for a thoughtful choice.

In addition, consider the feed mechanism. Some machines use a manual feed, while others are powered. The powered options enhance speed but can introduce inconsistency. Data reveals that 45% of woodworkers prefer manual feeds for better control. This decision is often reflective of individual skill levels. Ultimately, understanding these types and their features can pave the way for better decision-making in cabinet drilling.

When selecting a cabinet drilling machine, consider its key features carefully. The power of the motor is crucial. A stronger motor allows for more efficient drilling, especially in dense materials. Look for machines that offer variable speed settings. This feature gives you control over the drilling process and can affect the quality of your holes.

Another aspect to evaluate is the size and weight of the machine. A compact design can be beneficial for smaller workshops. However, larger machines may offer better stability during operation. Mobility is also an important consideration. Some models have wheels, making them easier to relocate. This could be critical in a busy workspace.

Don’t overlook the importance of safety features. A reliable machine should have safeguards to prevent accidents during operation. Additionally, examine the catalog of attachments and accessories available. This can enhance the machine's versatility, allowing for various drilling tasks. Reflect on your specific needs. Picking a machine without deep consideration may lead to dissatisfaction later.

When evaluating the build quality and durability of cabinet drilling machines, material choices play a crucial role. High-grade materials like cast iron and reinforced steel often offer better longevity. According to industry reports, machines constructed with these materials can last up to 20% longer than those made with weaker components. Furthermore, the precision of manufacturing affects long-term performance. Tighter tolerances typically mean less wear over time, maintaining accuracy for projects.

It's also essential to consider how machines handle vibrations. Machines with effective vibration-damping features can reduce wear and tear. Studies indicate that reduced vibration can increase a drilling machine's lifespan by around 15%. Regular maintenance can help mitigate some durability challenges, yet poorly designed machines will still suffer.

Pay attention to the design of the internal mechanisms. Complex systems may lead to breakdowns if not engineered correctly. It’s common to see machines that looked sturdy on the outside fail under rigorous use. Inspection of user reviews often reveals mixed experiences, showing that even reputable choices may have hidden flaws. A thoughtful evaluation of both build quality and user experiences can significantly influence the right buying decision.

| Feature | Description | Importance | Durability Rating |

|---|---|---|---|

| Motor Power | Indicates the strength for various drilling operations. | High | 4/5 |

| Build Material | The material used which affects longevity and sturdiness. | Very High | 5/5 |

| Precision | Accuracy in drilling holes, critical for cabinet making. | High | 4/5 |

| Weight | Portability aspect and stability during operations. | Moderate | 3/5 |

| Ease of Use | User-friendly controls and setup process. | High | 4/5 |

| Maintenance | Frequency and simplicity of required maintenance tasks. | High | 4/5 |

When selecting a cabinet drilling machine, size plays a critical role. The dimensions of the machine should fit your workspace without compromising efficiency. Industry reports suggest that about 30% of woodworking projects fail due to poor equipment compatibility. Compact models may work for small workshops, but larger projects often require more advanced machines. Ensuring the correct size can mean the difference between a successful build and frustration.

Another factor to consider is the drill bit compatibility. Many machines support a variety of bit sizes and styles. According to a recent survey, around 40% of cabinet makers underestimate the importance of this compatibility. It’s essential to verify that the drill machine you choose can handle the necessary bit sizes for the materials you’re using. Drilling through different wood types requires specific bits to ensure clean cuts. Oversized bits can damage materials. Misjudging this compatibility can lead to costly mistakes and wasted time.

Accurate measurements and assessments significantly impact project outcomes. Each cabinet project presents its unique challenges. Some may require specific depth settings or precision drilling. Not accounting for these factors can yield unsatisfactory results. It's worth investing time to reflect on these details before making a decision. A poorly chosen machine can hinder creativity and project quality.

Budgeting for cabinet drilling machines is crucial. You must find a balance between price and quality that suits your needs. A higher price often indicates better materials and technology. However, it doesn’t always mean it’s the best choice for you. Sometimes, mid-range options perform quite well and save you money.

Consider your specific projects. If you drill frequently, investing more may pay off. But for occasional use, a budget-friendly model might suffice. Look closely at the features. You might notice some essential functions missing in cheaper models. These could affect your work quality. Reflect on how often you drill and your requirements.

Make a list of must-have features. This can guide your decision process. Compare models online, but remember to check user reviews. They often reveal performance insights that specs don’t cover. Avoid rushing your purchase; it's worth taking the time to reflect on your options.