In the ever-evolving landscape of precision manufacturing, the emergence of advanced technologies is shaping the future of industrial processes. Among these innovations, 4-Axis Machines are leading the charge, offering unprecedented precision and efficiency that can transform production lines. As we look ahead to 2025, five standout models are set to revolutionize the manufacturing sector with a remarkable 20 percent increase in efficiency, making them essential tools for modern manufacturers seeking to enhance their competitive edge.

These 4-Axis Machines are not just about improved speed; they signify a transformative shift toward smarter manufacturing practices. By incorporating advanced automation and sophisticated software controls, these machines can achieve intricate designs and complex operations that were previously deemed unfeasible. This capability not only streamlines workflow but also reduces material waste, thereby contributing to a more sustainable manufacturing process.

As companies strive to meet increasing market demands and deliver high-quality products, investing in these state-of-the-art 4-Axis Machines will be pivotal. The following sections will delve into the specific features and advantages of these top models, exploring how they can redefine precision manufacturing in the years to come.

In recent years, the landscape of 4-axis machining technology has undergone significant advancements, driven by the demand for enhanced precision in manufacturing processes. One of the most notable trends is the integration of AI-driven systems that streamline operations and optimize efficiency. These intelligent solutions enable manufacturers to achieve a 20 percent increase in overall productivity, marking a substantial leap forward in precision machining.

Additionally, the adoption of smart robotics in conjunction with CNC technologies is reshaping production lines. The market for CNC milling machines is experiencing accelerated growth, fueled by Industry 4.0 principles and smart manufacturing methodologies. This synergy not only enhances the accuracy of complex machining tasks but also allows for greater flexibility in production, catering to diverse manufacturing needs. As 4-axis machines become increasingly sophisticated, the industry is poised to embrace new standards of excellence, pushing the boundaries of what is achievable in precision manufacturing.

As the manufacturing landscape evolves, the introduction of advanced 4-axis machines in 2025 promises to significantly enhance precision manufacturing processes. Industry reports indicate that the global CNC machine tools market is poised to grow by USD 21.9 billion from 2025 to 2029, driven largely by the demand for high-precision, multi-axis machining centers. The integration of artificial intelligence in these machines is not just a trend but a game-changer, enhancing operational efficiency by 20% compared to traditional manufacturing methods.

When selecting the leading 4-axis machines, certain key features become indispensable. These include enhanced data management capabilities and advanced turning functionalities, which allow for greater flexibility and precision in machining operations. Furthermore, the ability to manage asymmetrical fillets and new hole template editors are crucial for manufacturers looking to optimize their workflow and output quality. Such innovations are expected to set the standard in the realm of precision manufacturing as we approach the mid-2020s, reflecting a shift toward more adaptable and efficient manufacturing processes.

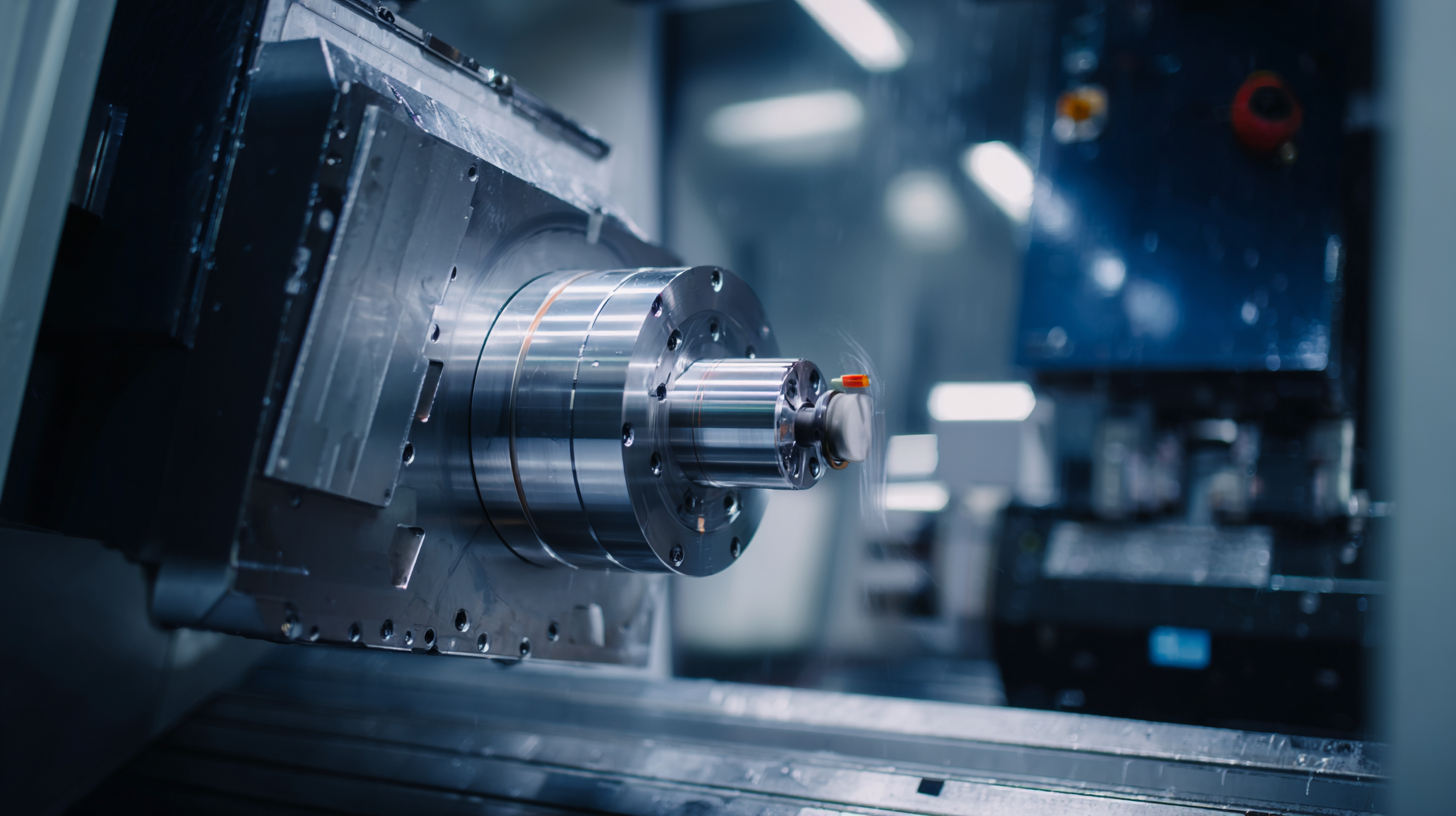

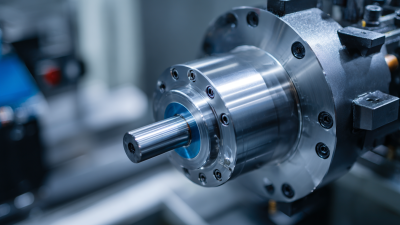

In the evolving landscape of precision manufacturing, 4-axis machines have emerged as transformative tools, delivering a remarkable 20 percent increase in efficiency. These machines expand upon the traditional 3-axis design by adding a fourth rotational axis, allowing for more complex geometries to be machined in a single setup. This not only reduces the need for multiple setups and manual adjustments but also significantly minimizes human error, leading to higher quality and consistency in production.

The enhanced capabilities of 4-axis machines further facilitate intricate part designs by enabling continuous machining operations. This capability streamlines the workflow, as operators can achieve complete machining cycles without the need to reposition the workpiece manually. Additionally, advanced software integration and automation processes allow for real-time monitoring and adjustments, optimizing machining parameters on the fly. Consequently, manufacturers can confidently increase production rates while maintaining precision, fostering a new era of efficiency and innovation in the industry.

In the realm of precision manufacturing, the introduction of advanced 4-axis machines is making significant waves across various industries. For instance, the aerospace sector has experienced transformative changes through the implementation of these machines. Companies are now able to achieve complex geometries and tighter tolerances that were previously deemed challenging. The efficiency improvements have led to faster turnaround times on critical components, enabling manufacturers to respond more swiftly to market demands.

Similarly, the automotive industry has reaped substantial benefits from adopting 4-axis machining technology. By optimizing production processes, manufacturers can reduce waste and enhance the consistency of their parts. Case studies reveal that integrating these machines has led to a remarkable 20 percent increase in efficiency, allowing producers to maximize output while maintaining high-quality standards. This has not only improved profitability but has also set a new benchmark for precision in automotive manufacturing.

This chart illustrates the efficiency improvement achieved by various industries utilizing advanced 4-axis machines in 2025. The percentage increase in efficiency shows the significant impact of these technologies on precision manufacturing processes.

The landscape of precision manufacturing is undergoing a significant transformation with the introduction of advanced 4-axis machinery. These innovative machines are designed to enhance the efficiency of manufacturing processes by allowing for simultaneous multi-axis operations. This capability not only reduces cycle times but also improves accuracy, making it a vital tool for industries demanding high precision, such as aerospace, automotive, and medical device manufacturing.

Future innovations in 4-axis machinery are expected to incorporate advanced technologies such as artificial intelligence and machine learning to further optimize production workflows. As manufacturers embrace IoT connectivity, these machines will enable real-time data analysis, leading to predictive maintenance and reduced downtime. Moreover, the integration of automation will streamline operations, allowing for more complex tasks to be completed with minimal human intervention. By revolutionizing the way parts are produced, these advancements promise to elevate manufacturing standards, ensuring that companies remain competitive in a rapidly evolving market.