The landscape of manufacturing technology is undergoing rapid transformation, with CNC drilling machines at the forefront of this evolution. As we project into 2025, the demand for precision and efficiency in drilling operations is expected to skyrocket, driven by the proliferation of advanced materials and the need for intricate designs across various industries. According to a recent report by MarketsandMarkets, the global CNC machine market is anticipated to reach USD 117 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 6.6%. This expansion highlights the critical role of CNC drilling machines as manufacturers seek to enhance productivity while maintaining the highest standards of accuracy.

In the context of advancing automation and the integration of Industry 4.0 practices, manufacturers are increasingly turning to smart CNC drilling machines equipped with IoT technology and adaptive software solutions. These innovations not only streamline production processes but also reduce the likelihood of errors, which could otherwise lead to costly downtimes. Furthermore, a report from Grand View Research indicates that the precision machine tools segment, which includes CNC drilling machines, is projected to grow significantly, exemplifying the industry's shift towards more efficient, high-performance solutions. As we delve into the specifics of the top CNC drilling machines anticipated for 2025, we will explore the features that contribute to their precision and efficiency, reshaping manufacturing practices for years to come.

CNC drilling machines play a pivotal role in modern manufacturing, providing the precision and efficiency required in various fabrication processes. These machines leverage computer numerical control technology, allowing for automated operations that enhance accuracy and reduce human error. In industries ranging from aerospace to automotive, the ability to produce intricate components with tight tolerances is essential, and CNC drilling machines stand out as a crucial tool for achieving these standards.

When investing in CNC drilling machines, it’s important to consider factors such as the machine's specifications, capabilities, and ease of integration into existing workflows. Regular maintenance and calibration are also vital to ensuring long-term performance and reliability.

**Tips:** Always research the latest advancements in CNC technology to stay updated on features that enhance productivity. Additionally, training operators in the best practices for machine operation can significantly improve the quality of output while minimizing operational downtime.

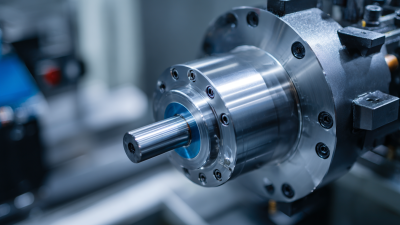

When selecting a CNC drilling machine, precision and efficiency are paramount. One of the key features to consider is the machine's spindle speed and torque. Higher spindle speeds allow for faster drilling without sacrificing accuracy, while sufficient torque is essential for handling various material types. Additionally, look for machines that offer variable speed control, enabling operators to adjust settings based on specific project requirements.

Another important feature is the machine's compatibility with different tooling systems. A versatile tool holder can significantly enhance the machine's capability, allowing it to perform various drilling operations with ease. It's also beneficial to consider machines equipped with automatic tool changers, as they can streamline production processes by reducing downtime between tasks.

**Tips:** Always assess the machine's rigidity and build quality, as this directly impacts its durability and performance. Furthermore, considering user-friendly programming interfaces can improve operator efficiency and reduce the learning curve for new users. Investing in a machine with robust software support can also enhance overall functionality, ensuring that your CNC drilling operations meet the highest standards of precision and efficiency.

In 2025, the CNC drilling machine market is set to feature an array of brands and models that excel in precision and efficiency, making significant strides in technology and design. The leading machines are equipped with advanced features such as automated tool changes, enhanced spindle speed, and robust software interfaces for easier programming. These developments not only improve drilling accuracy but also increase operational speed, allowing manufacturers to meet higher production demands with reduced downtime.

Among the top-performing models this year, some offer unique capabilities tailored to specific industries. This includes machines with multi-axis control for complex drilling operations, which position them as ideal choices for aerospace and automotive applications. Furthermore, user-friendly controls and real-time monitoring systems have become essential features that enhance usability and performance, ensuring that operators can optimize their workflows without extensive training. The ongoing evolution in CNC drilling technology emphasizes the importance of selecting the right model to enhance both productivity and the quality of finished products.

| Model | Drilling Diameter (mm) | Max Depth (mm) | Spindle Speed (RPM) | Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 12 | 25 | 3000 | 5 | 1500 |

| Model B | 10 | 20 | 4000 | 7.5 | 1750 |

| Model C | 15 | 30 | 2500 | 6 | 1600 |

| Model D | 8 | 15 | 3500 | 4 | 1400 |

The CNC drilling machine industry is witnessing rapid advancements driven by technological innovations aimed at enhancing precision and efficiency. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, highlighting a growing demand for high-precision drilling systems. These machines are increasingly integrated with artificial intelligence and machine learning algorithms that optimize drill patterns and reduce errors, resulting in tolerances as tight as ±0.001 inches in critical applications across aerospace, automotive, and electronics sectors.

Moreover, the advent of advanced materials, such as carbon fiber and high-strength alloys, necessitates the evolution of CNC drilling technologies. Recent studies from the International Journal of Advanced Manufacturing Technology indicate that modern CNC machines equipped with adaptive feed rate control can increase drilling speed by up to 30% while maintaining superior surface finish quality. Furthermore, the incorporation of IoT connectivity allows for real-time monitoring and predictive maintenance, significantly minimizing downtime and ensuring sustained operational effectiveness. As these innovations continue to unfold, the market anticipates a paradigm shift towards smarter, more efficient CNC drilling solutions that cater to the precision demands of future manufacturing.

The landscape of CNC drilling technology is poised for significant transformation by 2025, with emerging trends focusing on enhanced precision and efficiency. One major trend is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into CNC systems. According to a report by MarketsandMarkets, the AI in manufacturing market is projected to grow from $1.41 billion in 2021 to $16.7 billion by 2026, signaling a shift toward more intelligent manufacturing processes. AI-driven CNC drilling machines will not only optimize drilling parameters in real-time but also predict maintenance needs, leading to reduced downtime and increased productivity.

Another significant advancement is the adoption of hybrid manufacturing processes, which combine traditional CNC drilling with additive manufacturing. This approach allows manufacturers to create complex geometries with precision, minimizing material waste and enhancing overall efficiency. A study by Wohlers Associates projected that the global additive manufacturing market would reach $35.4 billion by 2024, further illustrating the potential for synergy between CNC drilling and additive techniques. This integration is expected to streamline operations, offering a marked improvement in both production rates and accuracy, making it indispensable for industries seeking to stay competitive in a rapidly evolving market.

Furthermore, the push towards sustainability in manufacturing will also influence CNC drilling technology. A report from NIST indicates that advanced manufacturing processes could potentially reduce energy consumption by up to 80%. As companies strive to meet environmental regulations and consumer demand for greener solutions, CNC drilling machines designed with energy efficiency in mind will play a pivotal role in minimizing carbon footprints while maintaining high levels of productivity. This focus on sustainability not only addresses environmental concerns but also drives innovation within the industry.