In the ever-evolving landscape of manufacturing, precision is crucial. The demand for high-quality components requires industry leaders to invest in efficient machinery. CNC drilling machines have emerged as indispensable tools for manufacturers aiming to enhance their production capabilities. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $117 billion by 2025, highlighting the growing importance of these technologies.

CNC drilling machines play a critical role in various sectors, including aerospace, automotive, and electronics. Their ability to deliver consistent accuracy elevates the manufacturing process. However, not all CNC drilling machines are created equal. Manufacturers must carefully evaluate their options to ensure they choose machines that align with their production goals and standards. Making the right choice can lead to significant cost savings and improved operational efficiency.

Yet, it is important to reflect on the challenges associated with CNC technology. The initial investment can be substantial, and ongoing maintenance is essential. Additionally, operators must possess the necessary skills to operate these machines effectively. As the industry continues to advance, staying informed about the latest innovations is vital for success and competitiveness in the market.

CNC drilling machines are crucial in modern manufacturing. They offer unmatched precision and speed. These machines operate using computer numerical control technology. This results in higher accuracy compared to manual drilling. The automation reduces human errors, enhancing production efficiency. However, not all machines are created equal. Some may struggle with complex geometries or tougher materials.

In production settings, CNC drilling machines play essential roles. They can process various materials, from wood to metal. The drilling process is customizable, allowing for different hole sizes. Operators must understand the machine settings thoroughly. Incorrect settings can lead to wasted materials and time. Maintenance is another critical aspect. Regular checks are necessary to avoid breakdowns. Skipping maintenance may cause inaccuracies and affect performance.

Investing in CNC technology can boost productivity significantly. However, it requires training and experience. Many manufacturers find the learning curve steep. Mistakes can be costly. Balancing efficiency with precision remains a challenge. Overall, CNC drilling machines can transform manufacturing processes when used correctly.

| Machine Model | Drilling Capacity (mm) | Spindle Speed (RPM) | Feed Rate (mm/min) | Precision (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 25 | 6000 | 1000 | 0.01 | 1500 |

| Model B | 30 | 5500 | 900 | 0.015 | 1600 |

| Model C | 20 | 7000 | 1100 | 0.02 | 1400 |

| Model D | 35 | 6500 | 950 | 0.012 | 1700 |

| Model E | 40 | 6000 | 1000 | 0.018 | 1650 |

| Model F | 15 | 7200 | 1200 | 0.025 | 1300 |

| Model G | 45 | 5800 | 850 | 0.02 | 1750 |

| Model H | 24 | 6400 | 1150 | 0.014 | 1450 |

| Model I | 50 | 5700 | 800 | 0.022 | 1800 |

| Model J | 22 | 7100 | 930 | 0.017 | 1550 |

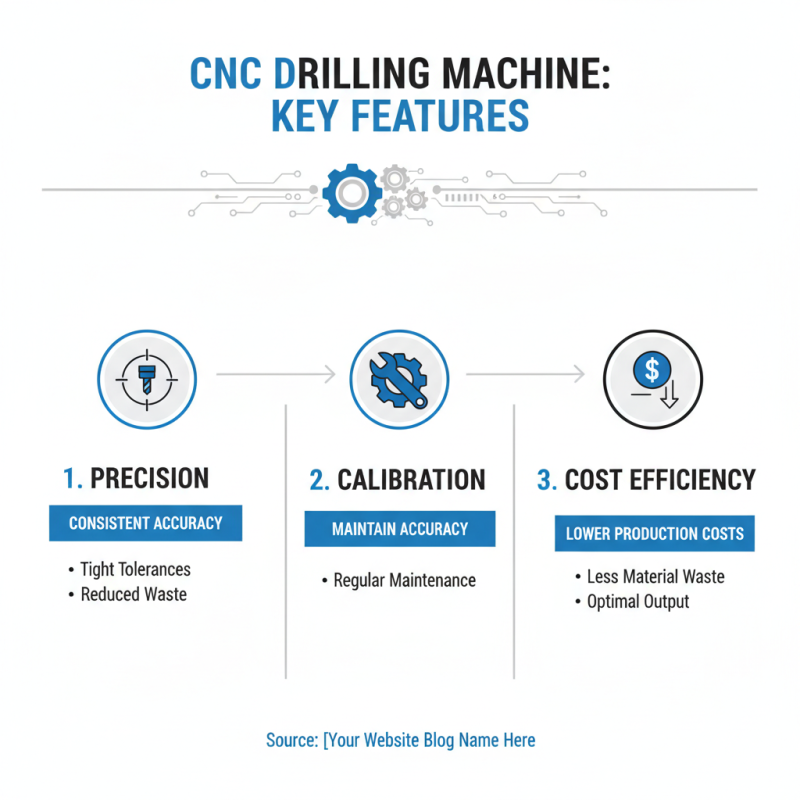

When choosing a CNC drilling machine, several key features should guide your decision. Precision is paramount. A machine must deliver consistent accuracy to ensure high-quality output. Look for models that boast tight tolerances. This precision often translates into reduced material waste and lowered production costs. However, maintaining that precision requires regular calibration. Sometimes, this step is overlooked.

Efficiency plays a crucial role as well. A machine with faster drilling speeds can significantly improve production times. Automated features, like tool changers, can also enhance productivity. Yet, these advanced functionalities might complicate maintenance. Some operators may struggle to manage the intricacies of modern machinery. It's essential to weigh the benefits of speed against the potential for operational hiccups.

Another vital aspect is user-friendliness. A straightforward control interface can reduce training times for new operators. However, the trade-off might be fewer customization options. Reviewers often highlight the balance between simplicity and versatility. Remember that what works for one shop may not fit another. Therefore, assessing your specific needs is crucial before making a choice.

CNC drilling machines provide unmatched precision and efficiency in modern manufacturing. Their popularity has surged, with reports noting that the global CNC machine market could reach $100 billion by 2025. This growth stems from the rise of automation in production processes.

Precision is vital for high-quality output. Data indicates that inaccuracies can lead to significant waste, potentially costing manufacturers thousands of dollars. High-end CNC machines typically feature advanced servo motors and feedback systems, enhancing their reliability. Many machines achieve drill tolerances as tight as ±0.005 inches, but achieving this requires skilled operators. Training is essential; miscalibrated machines can produce subpar results.

Efficiency improves with proper maintenance and technology integration. Some machines can operate continuously for long hours, but downtime for repairs can disrupt production. Predictive maintenance can reduce unexpected failures, yet many facilities overlook it. Implementing real-time monitoring systems could be beneficial. Regular updates on operating parameters may prevent minor issues from escalating into costly repairs.

When considering CNC drilling machines, efficiency is key. These machines vary in speed and accuracy.

Assessing performance can be challenging. Each model has strengths and weaknesses. Precision is essential in manufacturing, yet not all machines deliver equally.

Tips: Look for machines that offer a balance of speed and accuracy. Consider features like auto-tool change. Check if they can handle different materials effectively.

Some machines struggle with complex designs. Operators might face difficulties with newer technology. User feedback is crucial for selecting the right machine. Understanding individual requirements can optimize performance.

Tips: Regular maintenance is vital for longevity. Ensure staff are trained to operate machinery properly. Review user manuals for best practices to enhance efficiency.

Efficiency in CNC drilling machines often comes down to design and operation. Cutting speeds vary widely. It’s important to compare multiple models.

Selecting the right machine needs thoughtful consideration. Ignoring specifics can lead to inefficiencies.

CNC drilling technology is rapidly evolving. As manufacturers strive for precision, several trends emerge. One key trend is the integration of artificial intelligence. AI can optimize drilling processes, reduce waste, and enhance accuracy. Reports show that AI-driven CNC machines can improve productivity by up to 30%. This change is particularly vital in competitive markets.

Another significant advancement is the use of advanced materials. Lightweight composites are gaining traction in aerospace and automotive sectors. These materials require tailored drilling techniques. Current machines may not always meet these specific needs. This gap invites reflection on machine adaptability and the necessity for ongoing training. Investing in new technologies without proper understanding can lead to inefficiencies.

Sustainability trends also shape the manufacturing landscape. Companies seek eco-friendly processes that minimize waste. A recent survey indicated that 70% of manufacturers prioritize sustainability in their operations. However, implementing sustainable practices does not come without challenges. Transitioning to green technologies can be costly and complex. Balancing costs while maintaining efficiency remains a pressing concern.