In the rapidly evolving landscape of manufacturing and woodworking, the role of **Panel Drilling Machines** has become increasingly critical for achieving both precision and efficiency in production. According to a recent market analysis by Grand View Research, the global woodworking machinery market is projected to reach $11.8 billion by 2025, driven largely by advancements in technology and the growing demand for high-quality precision tools. As the industry shifts towards greater automation and smart manufacturing solutions, panel drilling machines are positioned to play a pivotal role, enabling manufacturers to meet rising demands while maintaining stringent quality standards.

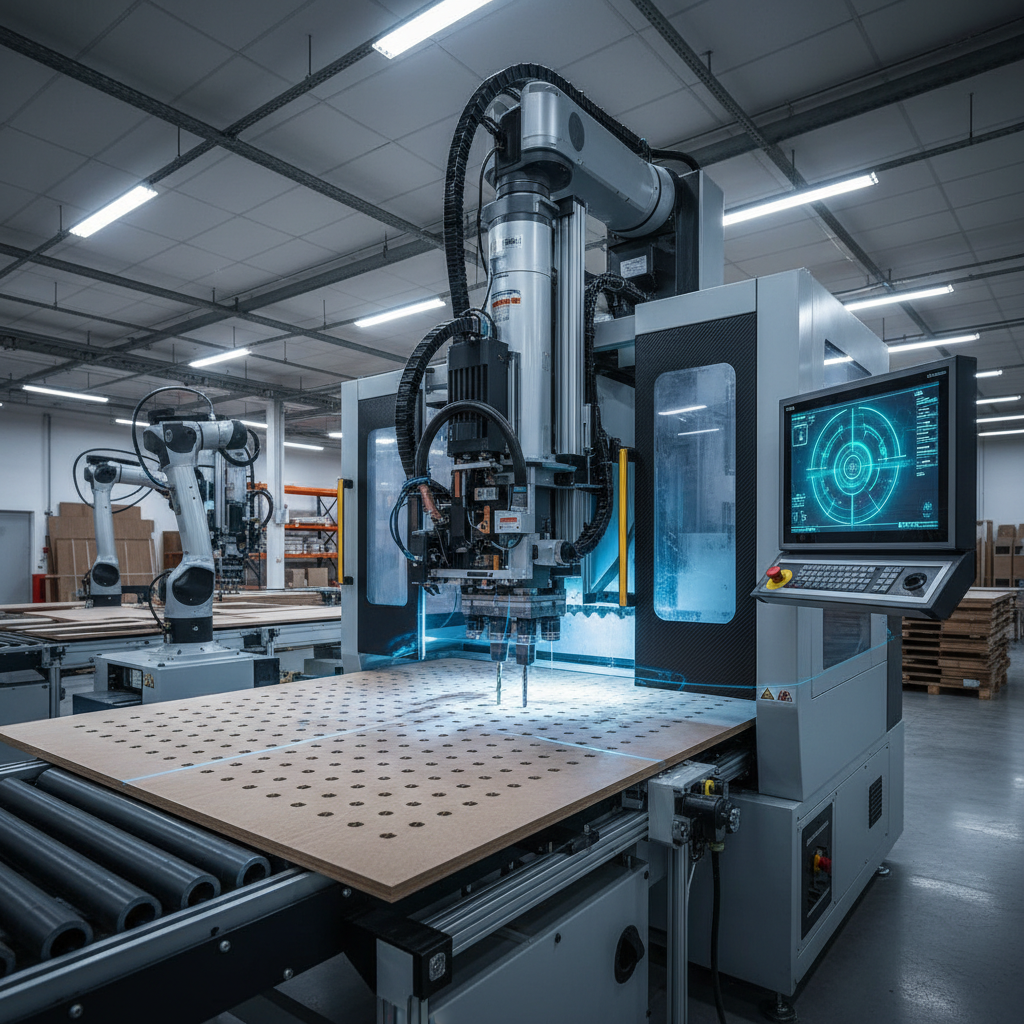

As we delve into the “Top 2025 Panel Drilling Machines,” it is essential to recognize that these machines are not only fundamental tools in workshops but also represent a significant investment in operational efficiency. With features that enhance speed, accuracy, and versatility, the best models for 2025 are designed to cater to various applications, from simple drilling to complex multi-dimensional tasks. Reports indicate that machines with advanced CNC capabilities are expected to dominate the market, as they offer greater flexibility and a higher return on investment. With manufacturers continuously innovating and optimizing their processes, the selection of the right panel drilling machine becomes crucial for businesses striving to enhance productivity and reduce production costs.

When evaluating the top panel drilling machines for 2025, precision stands out as a crucial feature defining their effectiveness. Advanced spindle designs and high-speed motors significantly enhance drilling accuracy, allowing for cleaner cuts and better overall material integrity. Machines that incorporate CNC (Computer Numerical Control) technology also contribute to precision, ensuring that each drill is consistently placed with optimal repeatability. This technological integration reduces human error and increases production efficiency, making such machines invaluable for both small workshops and large manufacturing operations.

In addition to spindle performance, other features that enhance precision include the alignment systems and the durability of the drill bits used. Laser alignment systems provide operators with real-time feedback, ensuring that each drilling action is precisely executed according to specifications. Furthermore, premium materials and innovative coatings for drill bits allow for a longer lifespan and a cleaner drilling process, minimizing the chances of splintering or chipping. As the landscape of panel drilling technology evolves, these features will be key in maintaining high standards of quality and efficiency that meet the demands of modern manufacturing.

When selecting the best panel drilling machines for 2025, understanding efficiency ratings is crucial. These ratings help businesses gauge how well a machine performs in terms of speed, power consumption, and durability. Leading models now incorporate advanced technology that not only enhances precision but also reduces waste, making them ideal for high-volume operations.

Tip: Always examine manufacturers’ efficiency ratings when browsing for panel drilling machines. Machines boasting higher ratings often lead to significant cost savings over time due to lower energy consumption and increased productivity.

In addition to efficiency ratings, other key industry metrics such as reliability and ease of maintenance should not be overlooked. A machine that can operate tirelessly while requiring minimal downtime is invaluable for sustaining high output levels. Investing in features like quick-change tooling systems can further enhance operational efficiency.

Tip: Consider investing in training for your team on the latest drilling technologies and maintenance procedures. This proactive approach can ensure that your machines run at optimal performance, prolonging their lifespan and maintaining efficiency in your production line.

When selecting a panel drilling machine for your woodworking shop or manufacturing facility, cost-effectiveness should be a primary factor in your decision-making process. The top 2025 panel drilling machines offer a range of features that enhance precision and efficiency, yet they come at varying price points. A comparative analysis reveals that investing in higher-end models often yields better long-term savings due to their durability and reduced maintenance costs. Therefore, conducting thorough research on both initial costs and operational expenses can lead to more informed purchasing choices.

**Tips for choosing a cost-effective panel drilling machine:**

- Assess the volume of work: If you are handling high-volume production, a more expensive machine with faster drilling speeds and automation may justify the higher initial investment.

- Consider energy efficiency: Look for models with energy-saving features. Machines that consume less power can significantly lower operational costs over time.

- Evaluate warranty and support: Always check the warranty terms and the manufacturer’s support. Machines with longer warranties and reliable customer service may save you money on repairs and downtime in the future.

By focusing on these factors, one can effectively weigh the cost against the expected returns, ensuring that the selected panel drilling machine meets both budgetary constraints and operational needs.

The integration of smart technology in panel drilling machines is poised to redefine industry standards, emphasizing precision and efficiency in operations. As observed in related fields such as offshore drilling and mining, the push towards automated solutions is driving a significant transformation. By 2025, over 60% of new industrial equipment will adopt advanced automation and digital integration, reflecting an urgency for enhanced operational capabilities. This trend highlights a growing recognition of the value automation brings—not only in increasing efficiency but also in ensuring safety across various sectors.

Innovations in smart technology are not confined to any single industry; they transcend boundaries, as seen in the development of smart oil platforms that improve safety measures in deep-water operations. As smart home technologies evolved into essential features rather than mere luxuries, similarly, the panel drilling machines of the future will leverage intelligent systems for better performance. With a focus on smart technology, the design and functionality of panel drilling machinery will likely incorporate features that allow for real-time monitoring, predictive maintenance, and optimized performance, ensuring they remain at the forefront of the industry landscape. This evolution sets the stage for a new era where efficiency and precision are paramount, driven by technology tailored to meet the demands of modern manufacturing processes.

When evaluating the top panel drilling machines of 2025, user feedback highlights the real-world performance that can significantly affect purchasing decisions. Many users have reported on the impressive precision offered by these machines, with some models consistently delivering clean and accurate holes even in the most challenging materials. Efficiency also stands out as a recurring theme, with operators noting quicker setups and reduced downtime as crucial benefits in their daily operations.

To maximize the performance of these advanced machines, here are a few tips: First, always ensure proper maintenance to keep the equipment in optimal condition. Regular cleaning and timely part replacements can extend the machine's lifespan and enhance its precision. Second, invest in quality drill bits that match the material being worked on; this not only speeds up the drilling process but also improves hole quality. Lastly, don't overlook the importance of staff training; well-trained operators can leverage the machine's capabilities effectively, leading to better overall results and productivity.

| Model | Drilling Speed (RPM) | Max Drilling Depth (mm) | Precision (mm) | User Rating (out of 5) | Comments |

|---|---|---|---|---|---|

| Model A | 1200 | 30 | 0.02 | 4.5 | Excellent precision and ease of use. |

| Model B | 1000 | 28 | 0.03 | 4.0 | Good performance for the price. |

| Model C | 1400 | 35 | 0.015 | 4.7 | Highly rated for durability and performance. |

| Model D | 1100 | 25 | 0.025 | 4.3 | Perfect for small workshops. |