In the ever-evolving world of craftsmanship, the quest for precision and efficiency is paramount. A reliable CNC router has emerged as a transformative tool that not only enhances the quality of craftsmanship but also streamlines the entire creative process. By offering unparalleled accuracy and the flexibility to execute intricate designs, a reliable CNC router empowers craftsmen to push their creative boundaries and bring their visions to life. Whether one is a seasoned professional or an enthusiastic hobbyist, integrating this advanced machinery into their workflow can significantly elevate the standard of their work. This guide aims to explore the various ways a reliable CNC router can unlock new levels of precision and innovation in your craftsmanship journey, illustrating its vital role in achieving exceptional results in woodworking, metalworking, and other artistic endeavors.

CNC routers have revolutionized the world of precision crafting, allowing artisans to transform intricate designs into reality with unparalleled accuracy. Understanding how these machines operate is essential for anyone looking to elevate their woodworking skills.

A CNC router utilizes computer numerical control to guide the cutting tool along specified paths. This means that complex shapes, curves, and details can be replicated consistently, ensuring that no matter how many pieces you create, each one will meet exacting standards.

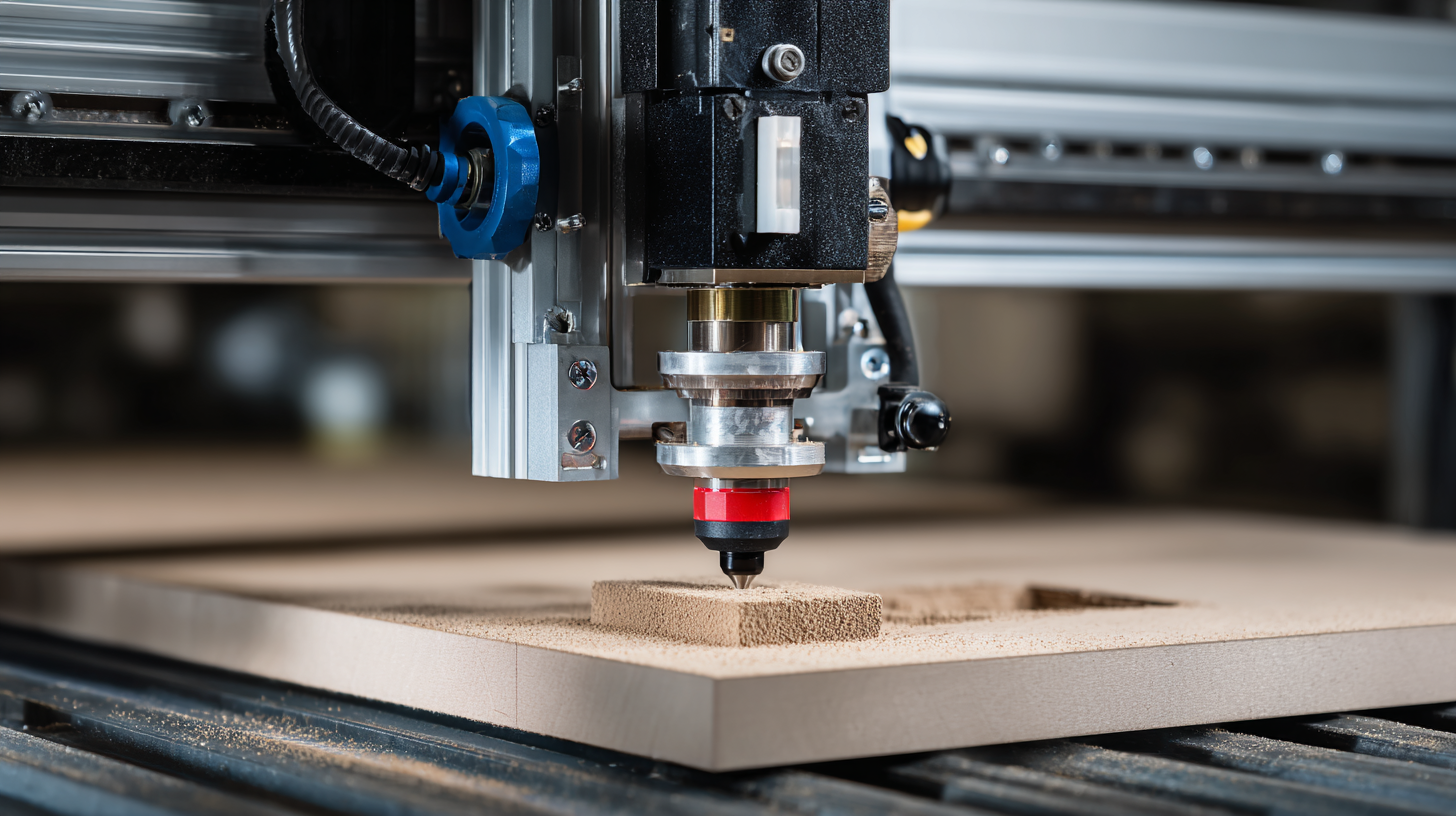

Moreover, the versatility of CNC routers extends beyond simple cuts. They can engrave, carve, and mill a wide range of materials, providing craftsmen the freedom to experiment with different textures and finishes. By integrating digital design software with CNC technology, creators can visualize their projects in 3D, making adjustments before production begins. This fusion of creativity and technology not only streamlines the crafting process but also empowers artisans to push the boundaries of their craft, producing work that is both precise and imaginative.

Embracing CNC routers opens doors to limitless possibilities in woodworking, making it an essential tool for those serious about their craftsmanship journey.

When it comes to enhancing craftsmanship, a reliable CNC router is an indispensable tool for artisans and manufacturers alike. According to a report by the International Federation of Robotics, the adoption of CNC technology has increased productivity by up to 20% across various manufacturing sectors. This rise underscores the importance of precision and efficiency that a high-quality CNC router brings, allowing craftsmen to focus on the intricacies of their work rather than the technical limitations of their tools.

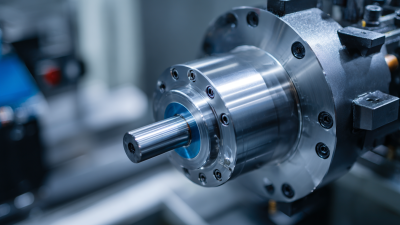

Key features of a reliable CNC router include accurate positioning systems, effective spindle power, and sturdy construction. For instance, routers equipped with servo motors can achieve positioning accuracy as precise as 0.001 inches, drastically reducing production errors. Furthermore, routers with powerful spindles, rated at 3 to 8 kW, can handle a variety of materials, from softwood to hard metals, enabling craftsmen to expand their creative capabilities. Additionally, a robust frame design minimizes vibrations, which is vital for maintaining precision during intricate cuts. Ultimately, these features not only enhance productivity but also elevate the overall quality of craftsmanship.

| Feature | Description | Importance | Impact on Craftsmanship |

|---|---|---|---|

| Precision Mechanism | High-quality linear guides and ball screws | Essential for accuracy in cutting | Enhances detail and finish of projects |

| Software Compatibility | Compatible with industry-standard CAD/CAM software | Facilitates design and machining process | Allows for complex designs and automation |

| Motor Power | High torque motors for better cutting performance | Crucial for cutting through various materials | Provides versatility in project materials |

| Control System | User-friendly interface for ease of operation | Important for user efficiency and learning curve | Increases productivity and reduces errors |

| Stability and Rigidity | Robust frame construction to minimize vibrations | Vital for maintaining precision during cuts | Results in cleaner cuts and improved finish quality |

Setting up your CNC router for optimal performance is critical to unlocking its full potential in enhancing your craftsmanship. Start by selecting a stable workspace, as vibrations from an uneven surface can affect cutting accuracy. According to a report by the International Journal of Advanced Manufacturing Technology, maintaining a consistent setup improves precision by up to 45%. Additionally, ensuring that your CNC router is calibrated correctly is paramount; this involves adjusting the spindle speed and feed rates to match the materials you are using, which can significantly reduce tool wear and enhance finish quality.

Tips: To calibrate effectively, always use a high-quality dial gauge to check the alignment of the router against a known standard. Regularly inspect your tools for wear and replace them when necessary. Consider investing in a dust collection system, which can improve visibility and tool longevity by reducing debris accumulation.

Next, software setup is equally important. Utilizing the latest CAD/CAM software not only streamlines the design process but also allows for precise control over machining operations. Data from the National Institute of Standards and Technology suggests that incorporating advanced software can enhance machining speed and accuracy by approximately 30%, making it a worthwhile investment for any serious craftsman. Always ensure your software and firmware are up to date for better compatibility and performance.

Maintaining the precision of your CNC router is essential for achieving the highest quality craftsmanship. Regular maintenance not only prolongs the lifespan of your machine but also ensures consistent results in your projects. Start by keeping the working area clean; dust and debris can interfere with the movement of the router components, leading to potential inaccuracies. Implement a routine schedule for cleaning various parts of the machine, including the rails, screws, and the spindle, to keep everything running smoothly.

Another crucial aspect of maintenance is lubrication. Properly lubricating the moving parts reduces friction and wear, which can affect the precision of your cuts. Use appropriate lubricants as recommended by the manufacturer, and check regularly for any signs of wear or damage. Additionally, always inspect the cutting tools for sharpness and replace them when necessary. Dull tools can cause uneven cuts and increase the likelihood of errors, making it critical to keep them in top condition for flawless craftsmanship.

CNC routers have become pivotal in enhancing craftsmanship across various industries, driven by their precision and versatility. According to a report by Technavio, the global CNC router market is expected to grow by over 16% annually through 2026, reflecting an increasing adoption of CNC technology among artisans and manufacturers. This growth is largely attributed to the ability of CNC routers to handle a broad range of materials, including wood, plastic, and metals, allowing for intricate designs that were previously challenging to achieve.

Common projects that benefit from CNC routers include custom furniture, intricate signage, and detailed prototyping. Techniques such as 3D carving and engraving enable craftsmen to push the boundaries of creativity. By leveraging the capabilities of CNC routers, artisans can ensure high repeatability and accuracy in their work, which is crucial in both bespoke projects and mass production. Reports suggest that incorporating CNC technology can reduce production time by up to 50%, enabling artisans to focus more on design innovation rather than manual labor. This technological advancement not only enhances craftsmanship but also elevates the overall quality of products in the market.